- Nominal diameter: 5 to 50 mm

- Nominal flow: 3 to 310 m³/h

- Voltages =/~ 24/230 V

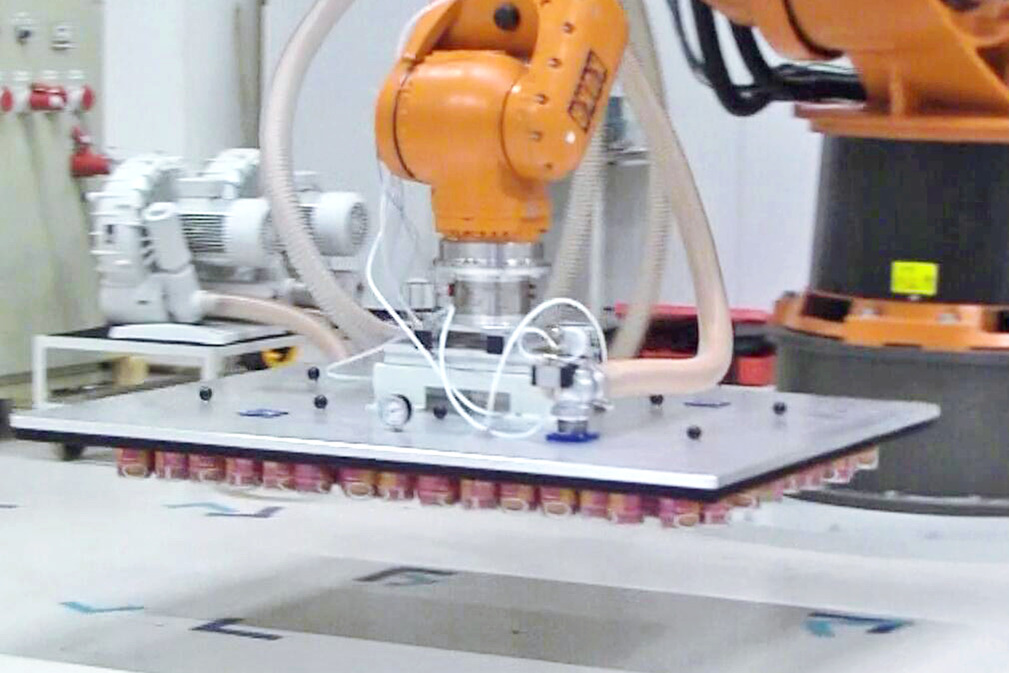

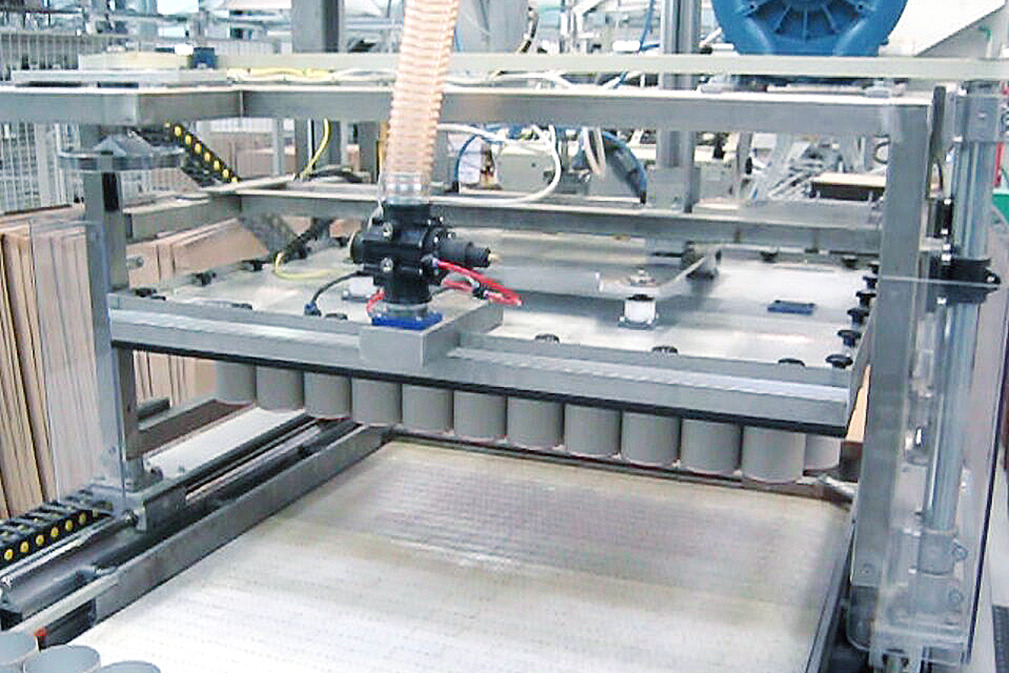

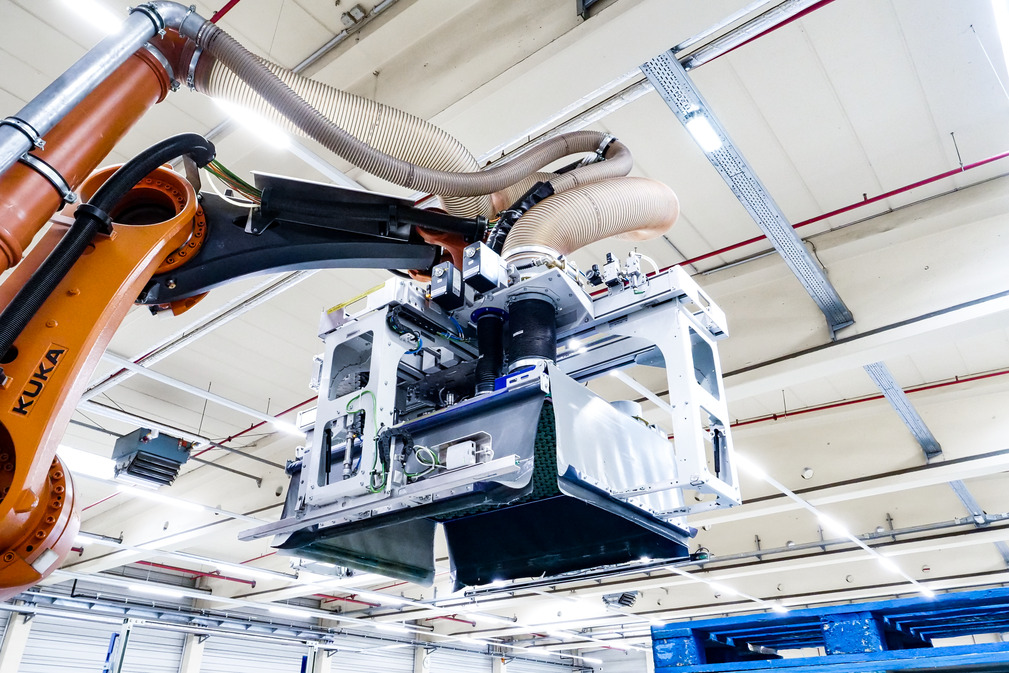

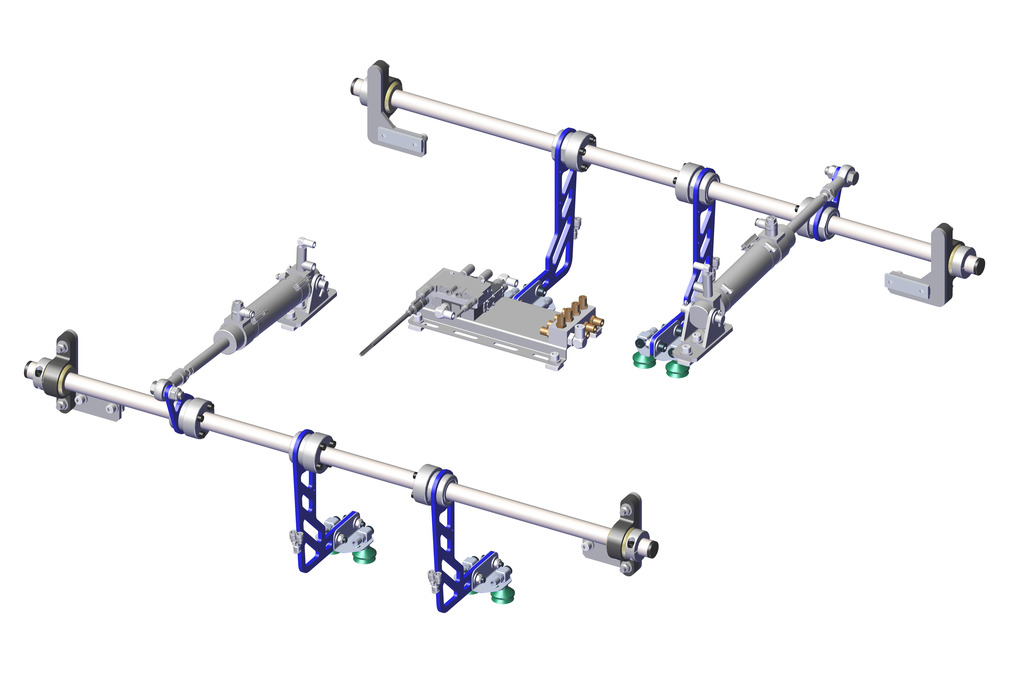

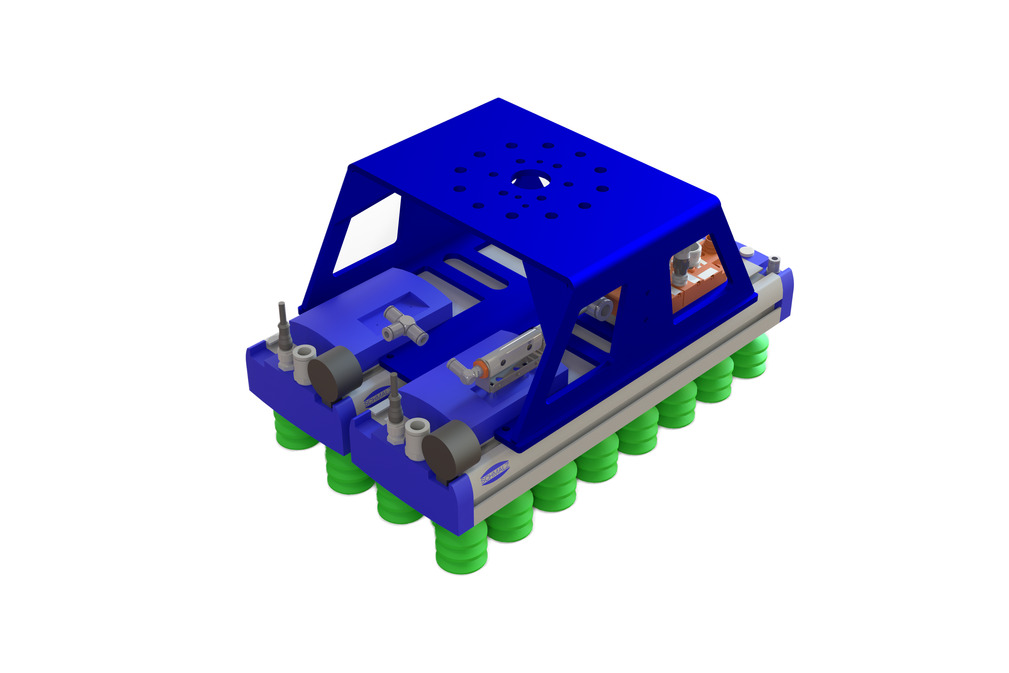

Layer gripper SPZ

Pick-and-place of unmixed workpiece layers

With the SPZ layer grippers, Schmalz offers solutions for palletizing or depalletizing workpiece layers such as cardboards, cans, jars, packaging and much more. Benefit from standardized assemblies combined into a ready-to-connect system suitable for your application.

Handling of layer weights up to 250 kg

Optimally coordinated gripping system incl. vacuum generation and controllable valves

Gripper design based on the workpiece layer

Minimized power of vacuum generation through workpiece-optimized design of the suction grid

Your Individual Configuration

The layer gripping systems are specially adapted to your applications. Contact us and receive a custom made offer.

Design

- Rigid flange (1) for connection to common robots and portals

- Optional: Spring-mounted flange to compensate for height differences in the workpiece layer (2)

- Gripper with sealing element made of plug-in suction cups (3) or sealing foam (4)

- Connector for external vacuum generation (5) or valve assembly (6)

Modular elements

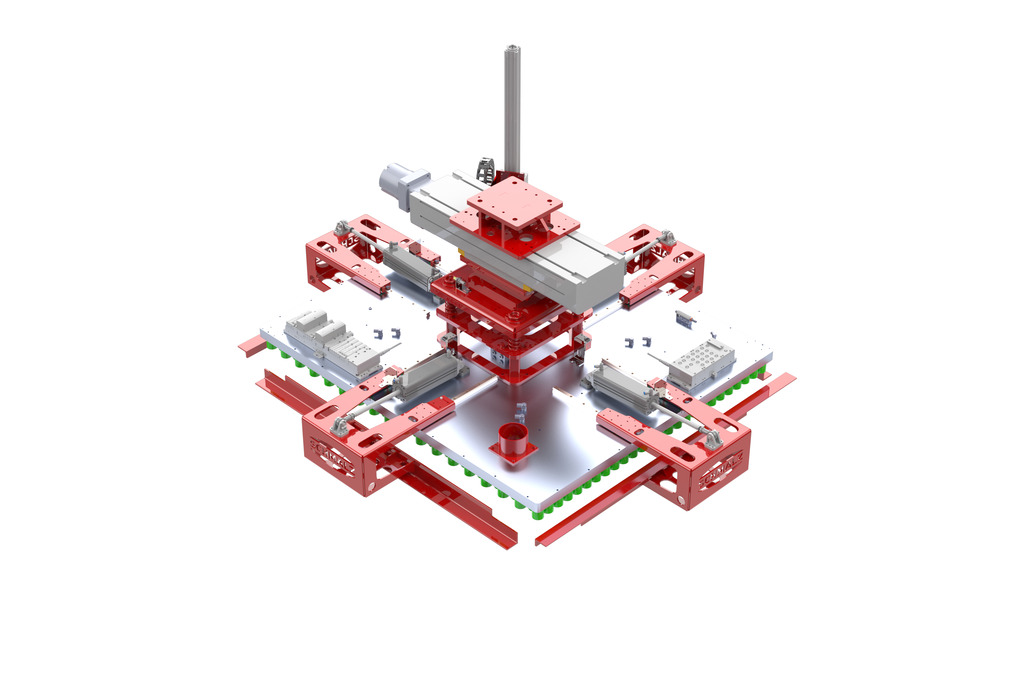

Pallet handling module

Optional module for applications where pallets also need to be handled.

Intermediate layer and pallet handling module

Optional module for applications where pallets and/or intermediate layers also need to be handled.

.jpg)

Light grid module

Optional module for detecting the workpiece layer height.

.jpg)

Mechanical clamping

Optional mechanical clamping module in the gripping process for increased holding forces.

Ordering information

Product code

Similar to a part number, the product code is used to uniquely identify product configurations at Schmalz. The product code can be found on the product label or on the quotation or order. Do you have questions about your product or would you like to order a configuration again? Then please have this key ready when you contact Schmalz.

| Code | Type |

|---|---|

| SPZ | Standard layer gripper |

| Code | Type |

|---|---|

| RD | Rigid |

| FL | Spring-mounted |

| Code | LxW in mm |

|---|---|

| 1,250 x 1,050 | 1,250 x 1,050 |

| 1,250 x 850 | 1,250 x 850 |

| 850 x 650 | 850 x 650 |

| Code | Height/diameter in mm |

|---|---|

| O20KS | Sealing foam (H = 20)* |

| O20 | Sealing foam (H = 20)** |

| SPB2 40 | Suction cup (∅ = 40)*** |

*Universally applicable standard sealing foam with conically cut suction cells

**Universally applicable standard sealing foam with cylindrically cut suction cells

***Pluggable silicone bellows suction cups

| Code | Distance between suction points in mm |

|---|---|

| 20T | 20 |

| 30T | 30 |

| 45T | 45 |

| Code | Cross section in mm |

|---|---|

| SW80 | 0.8 (sealing foam O20KS) |

| SW100 | 1.0 (sealing foam O20) |

| SW120 | 1.2 (suction cup) |

| Code | Diameter in mm |

|---|---|

| G60 | Straight, Ø = 60 (external) |

| G75 | Straight, Ø = 75 (external) |

| G100 | Straight, Ø = 100 (external) |

Ordering information

The designation code describes the standardized configuration options of the layer gripper. If required, it is possible to add further individual functions. We are at your disposal for the project planning and design of your vacuum system.

Technical Data

- Maximum load capacity up to 250 kg

- Suitable for deep-freezing down to -30 °C

- Minimum gripper size 450 x 350 mm

- Maximum gripper size 1,500 x 1,500 mm

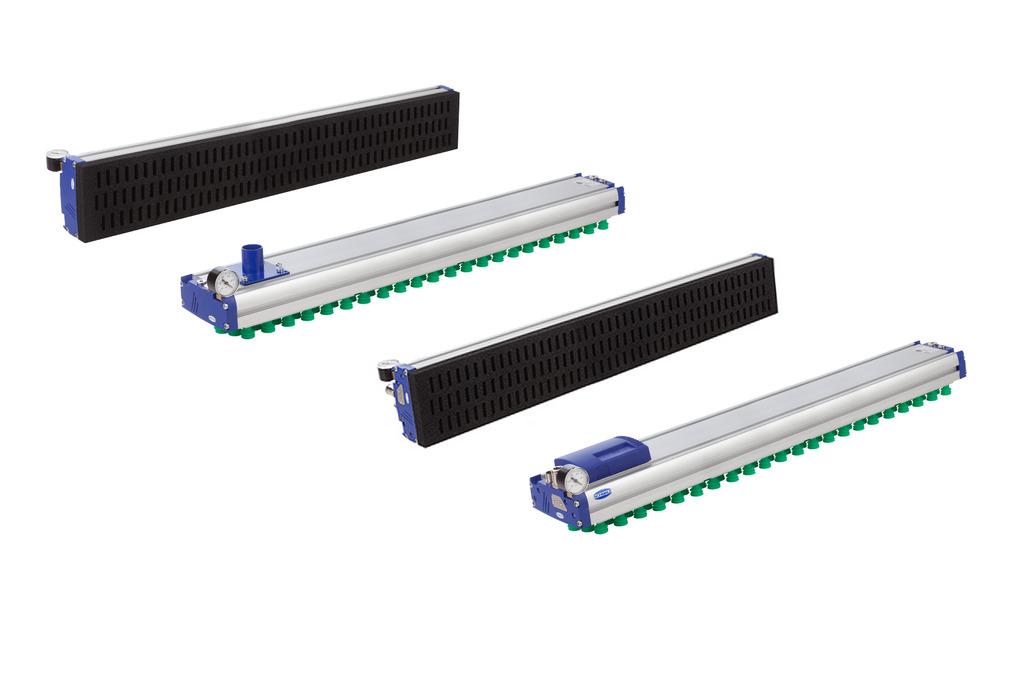

Example configurations

.jpg)

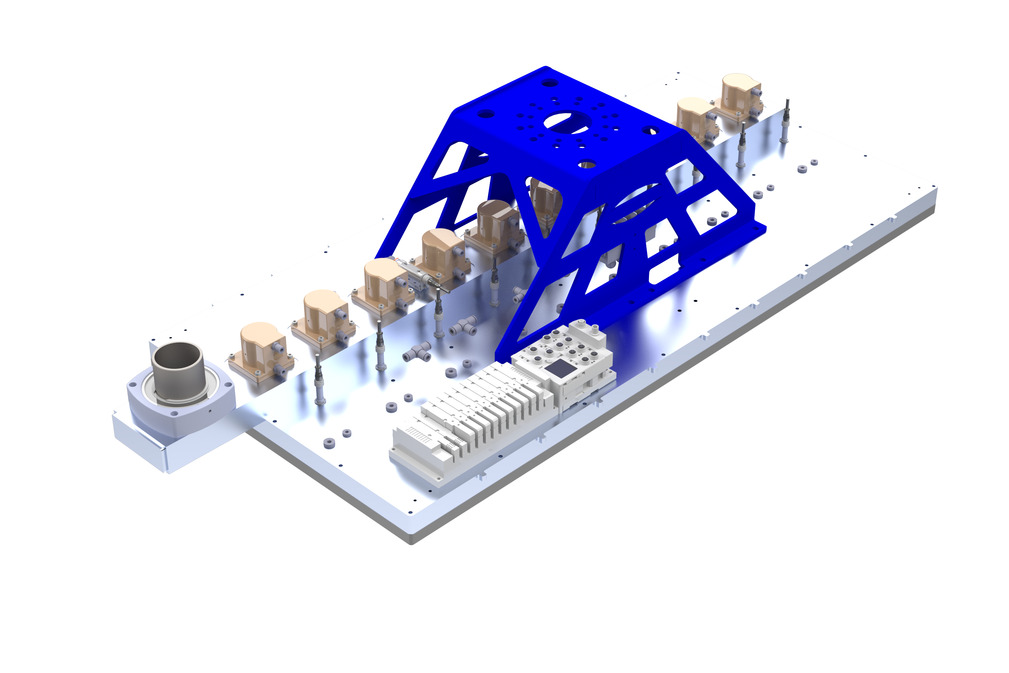

SPZ with suction cup carpet

- Handling of cardboard or other packaging

SPZ with sealing plate

- Handling of glasses, cans, buckets or other homogeneous workpiece layers

- Intermediate layer handling by means of retractable and extendable suction cups

SPZ with mechanical gripping support

- Mechanical gripping support for increased stability or increased gripping force

SPZ with x suction zones

- Formation of different segments that can be switched on and off

.jpg)

SPZ as blocked F-grippers

- Modular system for blocking area grippers (FMP, FMP-S, FXP, FXP-S)

- Row-by-row handling and individual loading and unloading of cardboards

SPZ for handling cardboard boxes

- blocked area grippers (FMP, FMP-S, FXP, FXP-S)

SPZ Nesting

- Stacking of waste-optimized wood or sheet metal blanks in just one handling process

Videos

Discover application examples of the product in various industries - user-friendly, informative and practical.

No suitable videos found? Then take a look at our media center.