EOAT is the key to flexible automation

Dr. Maik Fiedler explains the role of End of Arm Tooling as the key to flexible and efficient automation.

Dr. Fiedler, what role does EOAT play in automation?

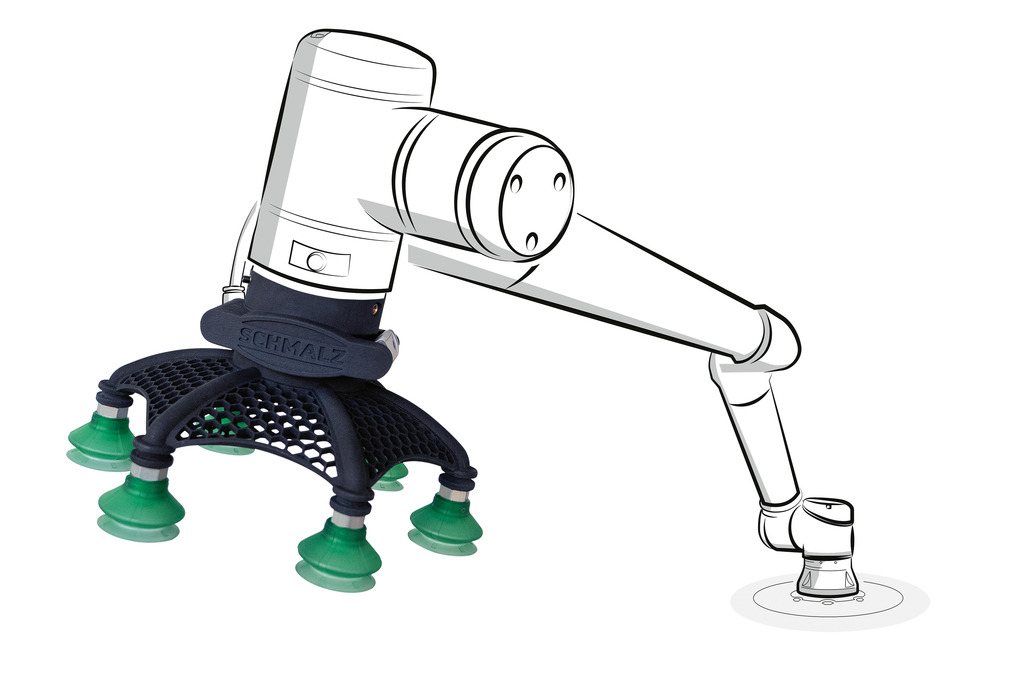

End of Arm Tooling is the interface between robots and other automation systems (e.g. packaging machines) and the workpiece. The robot cannot perform any task without a suitable gripping system. With the right EOAT, machines can be loaded and unloaded, workpieces palletized, packaged, assembled or handled in quality inspection. Our strategy is to provide robust, flexible and efficient solutions for all these applications.

With EOAT, we connect robots and workpieces - and thus create the basis for productivity, ergonomics and cost efficiency in automation.∼ Dr. Maik Fiedler (Member of the Executive Board and Head of the Vacuum Automation business unit)

Which gripper technologies do you use to achieve this flexibility?

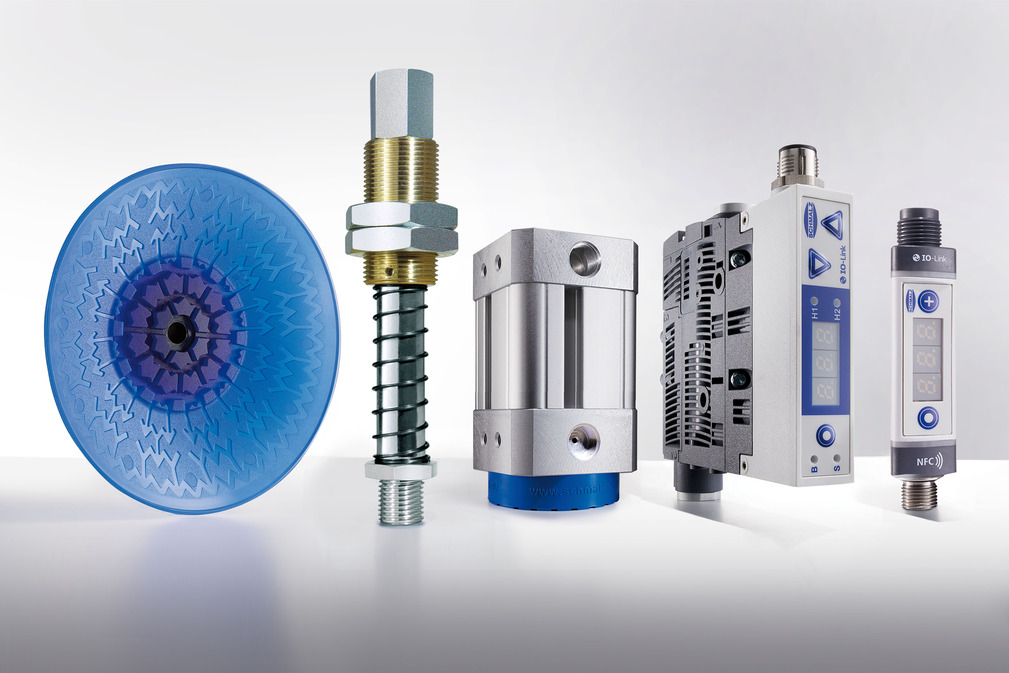

Our core competence lies in vacuum grippers. This technology is particularly versatile and enables the safe handling of a wide variety of workpieces - from cardboard boxes and sheet metal to glass or plastic parts. In addition, we use magnetic grippers for metal workpieces and mechanical grippers such as finger and needle grippers, which are particularly suitable for complex geometries or porous materials such as textiles.

Our EOAT can also be easily changed both manually and automatically. This not only minimizes set-up times, but also makes the systems highly flexible for a wide range of applications and workpieces.

We are also working on systems that allow automated part recognition and gripper selection. This allows robots to react even more flexibly and work reliably even in dynamic environments - for example in manufacturing, mounting or logistics.

Which fields of application are particularly important from your point of view?

EOAT is used in a variety of processes in a wide range of industries, such as the packaging, automotive and furniture industries. Typical tasks are pick-and-place or pick-and-pack operations, which are becoming increasingly important in logistics. In production, it is often a matter of moving sheet metal or components, loading machines or automating packaging steps. Our solutions also provide support in warehouse management when picking unsorted workpieces.

The key factor is that a wide range of gripper solutions can cover almost any handling task and specific challenges relating to workpieces, such as varying weights, surfaces, or even materials.

What added value does EOAT bring to users?

Automated handling undoubtedly offers a whole lot of advantages: it increases efficiency, process reliability and quality. It can be put into operation quickly and easily via plug and work and, thanks to its compatibility with common robot interfaces, allows a high degree of flexibility for a wide range of applications. Predictive maintenance prevents breakdowns and lengthy downtimes.

At the same time, it improves ergonomics for employees, as physically strenuous or monotonous activities are reduced. Less stress leads to less strain on health and can help to reduce absences due to illness.

Automation enables cost reductions through optimized processes and offers a high dimension of planning security. This is particularly important in view of the shortage of skilled workers.

What requirements do you have for the technical design?

Our customers expect robots to be able to handle a wide variety of workpieces with as few tool changes as possible. Adaptive gripping, i.e. systems that automatically adapt to different geometries, is therefore becoming increasingly important.

Lightweight construction and the use of energy-efficient materials also play a major role. One example is our lightweight gripper SLG, which can be precisely adapted to individual customer requirements online and without design knowledge and can be produced in a resource- and energy-efficient manner using 3D printing.

At the same time, we see a trend towards intelligent, connected solutions - such as grippers with integrated sensors that recognize workpieces and monitor the process. End of Arm Tooling is therefore increasingly becoming the key to the question of how flexible and economical robots can be. Our aim is to make this bridge between the automation system and the workpiece even more intelligent - and to offer our customers real added value in the long term.

Which developments will be decisive in the future?

We assume that the requirements for flexibility and adaptability will continue to increase. The automation of processes will also continue to become more important - whether in production, mounting or logistics.

Our goal therefore remains to provide systems that are reliable, efficient and of long-term value to the users.

Versatile and efficient: EOAT reliably covers a wide range of applications with vacuum technology.

Gentle but safe: finger grippers ensure that even sensitive food products are held securely.

Magnetic grippers move metal parts safely and reliably - ideal for fast automation processes.

Media contact

The Schmalz press team will be happy to answer any questions you may have.