AI (Artificial Intelligence)

Artificial intelligence (AI) refers to the process by which computers release tasks that require human intelligence. Typical examples include pattern recognition, decision-making, speech and image recognition and autonomous action.

The technical basis of AI is formed by methods such as machine learning (ML), deep learning (DL), neural networks and machine vision (industrial image processing). They make it possible to analyze large amounts of data, recognize patterns and optimize, automate and make processes more reliable step by step.

Fields of application of AI

Artificial intelligence is used in many industries today and is considered a driving force behind digitalization.

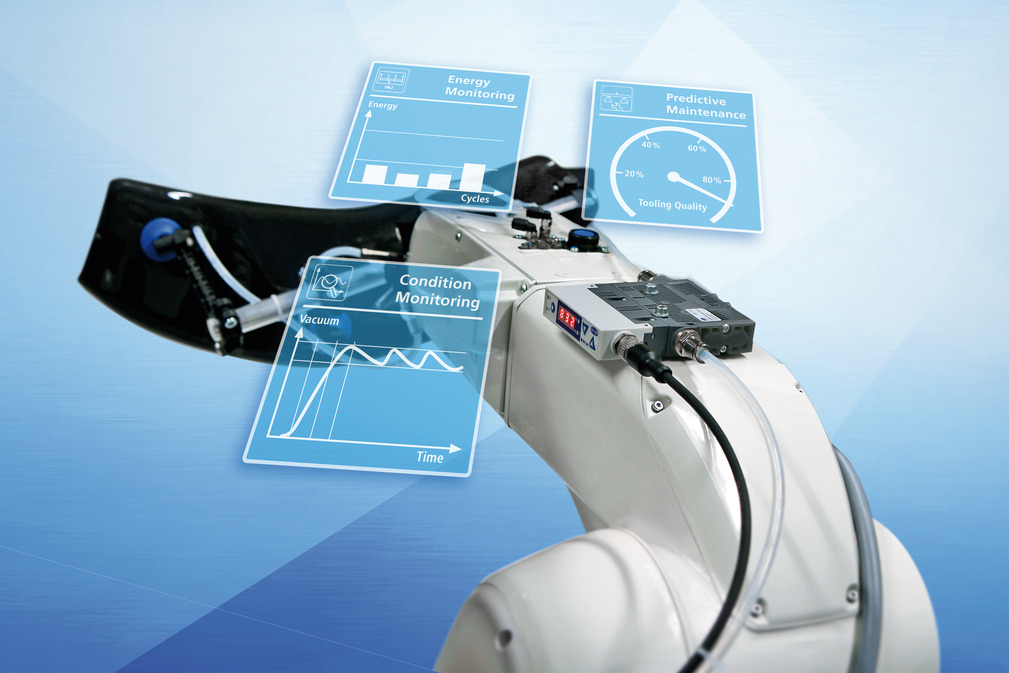

One important field is robotics and automation, where AI plans motion sequences, takes safety aspects into account and supports assistance systems. It also contributes to more intelligent production processes in Industry 4.0, for example through predictive maintenance, optimized cycle times and the data-supported control of production lines.

In medical technology, AI enables the analysis of imaging procedures and serves as valuable decision-making support for doctors.

In logistics and smart factories, it ensures more precise forecasts, optimized routes and inventories as well as powerful real-time data processing.

Finally, voice and text systems also play a major role: intelligent assistants, chatbots and automatic documentation and search functions have become a matter of course in many applications.

Artificial intelligence in vacuum technology

AI has a wide range of applications in vacuum technology. Condition monitoring, predictive maintenance and machine vision (image processing) are particularly important. Artificial intelligence is also used for the automated handling of workpieces, intelligent process controls, energy efficiency solutions, leak detection systems and networking in smart factory environments.

Process control, energy efficiency and leak detection

AI-based process control systems stabilize the process vacuum and control vacuum valves and vacuum chambers intelligently and as required. By evaluating real-time data in combination with historical measured values, energy consumption is optimized, load peaks are reduced and cycle times are shortened. In addition, leak detection systems supported by machine learning enable significantly faster and more reliable leakage detection, as they automatically identify and evaluate typical patterns in measurement curves.

Connectivity in the smart factory

In the smart factory, vacuum components are connected to Industry 4.0 environments via IoT interfaces. There, artificial intelligence (AI) collects measured values from the sensors and control systems, evaluates them and controls the processes. This provides the basis for data processing for analysis and seamless traceability. The direct connection to ERP systems enables end-to-end workflows to be implemented - from order planning to quality documentation.

Advantages of AI in production and the world of work

The use of artificial intelligence (AI) offers clear advantages in production and in the world of work.

AI systems enable targeted process optimization in production, increase efficiency and improve quality assurance. Intelligent automation speeds up processes, uses resources more economically and increases plant availability. In the smart factory, this leads to transparent workflows, adaptive production concepts and a sustainable increase in competitiveness.

AI also reduces the workload in the workplace: routine tasks are taken over, while employees gain more time for creative and value-adding activities.