CAD becomes reality: Schmalz transforms your design data into digitally designed gripping solutions for automated sheet metal handling

Experience a real premiere at Blechexpo in Stuttgart: Schmalz will be presenting an innovation that will allow you to speed up your design processes by up to 80 %. We are revolutionizing digital design and setting new standards in sheet metal handling. In Hall 1, Stand 1110, you can expect intelligent, flexible grippers that can be precisely adapted to your requirements, as well as digital designs of custom-made gripping solutions that are derived directly from your CAD data. The portfolio is supplemented by powerful vacuum lifting devices that not only make your processes more efficient, but also significantly more ergonomic. Discover the future of handling sheet metal - live at Schmalz.

Vacuum Automation

Highlights

Automation is becoming increasingly important in sheet metal and metal handling. We will be presenting our broad portfolio at Blechexpo: From smart, flexible grippers to digital designs of custom-made gripping solutions and AI-based software solutions. Find the perfect solution for your sheet metal processing and experience the future of sheet metal processing with Schmalz.

Everything under control!

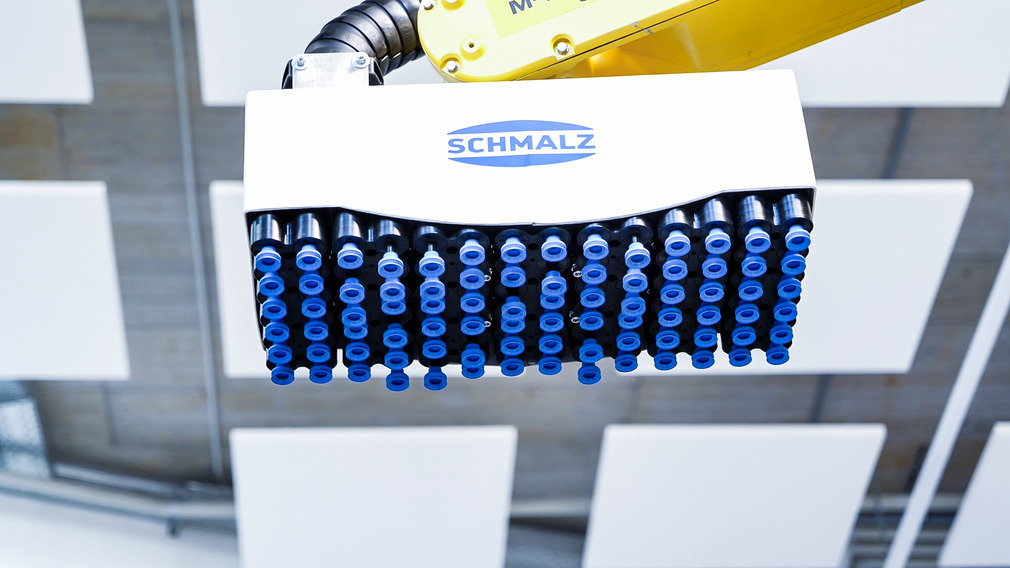

The matrix area gripper FMG is a compact gripping module for the design of flexible area grippers. Perfect for loading and unloading deburring and straightening machines and for sorting workpieces from laser, punching, nesting and cutting machines. Flat and air-tight workpieces of various shapes and sizes can be handled effortlessly. The twelve individually controllable suction cups guarantee maximum flexibility.

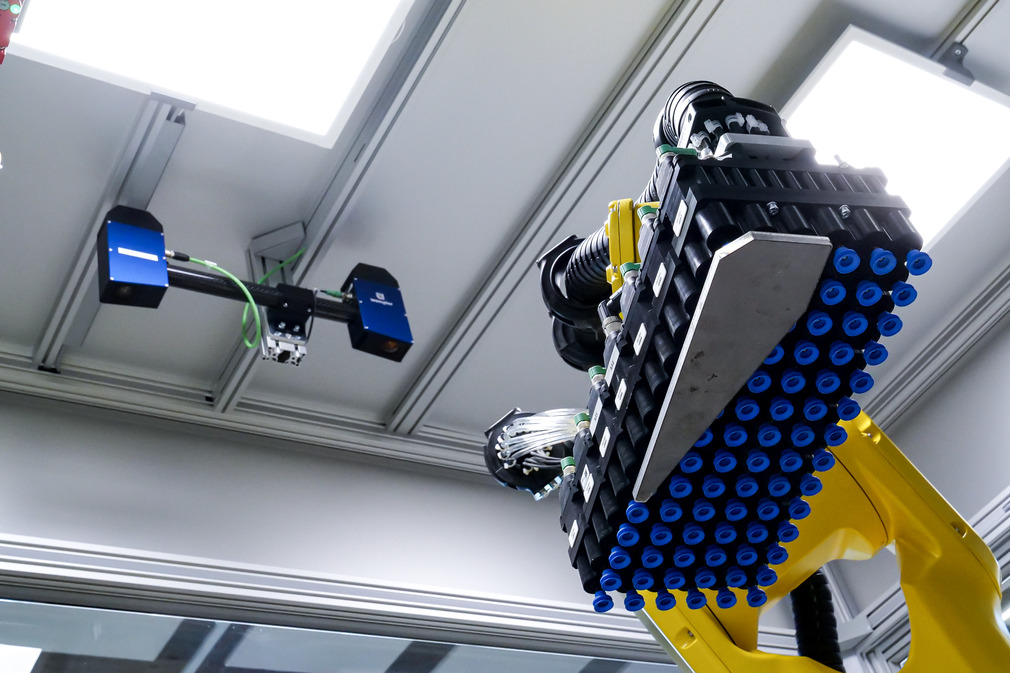

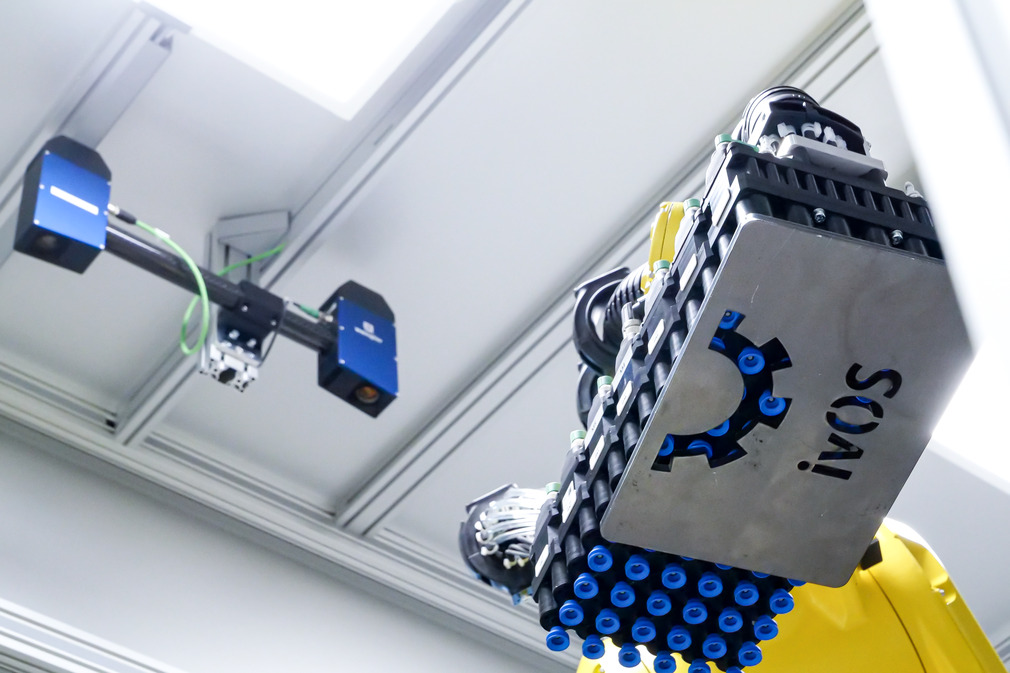

Intelligent Gripping - Ready to automate sheet metal handling

The Solution Kit ivOS Sheet Metal is the ideal solution for automating the loading and unloading of sanding, deburring, straightening and laser cutting machines. Thanks to its capability to autonomously and intelligently grip unknown objects, the system enables the economical use of robots, even with small batch sizes and high variance. The best thing about the plug and play solution is that neither programming knowledge nor adaptations by experts are required. Our solution uses state-of-the-art robotics technologies such as AI software and 3D vision sensors for precise handling and automation. The integrated matrix area gripper FMG controls suitable suction cups to grip individual sheet metal shapes.

Small but mighty!

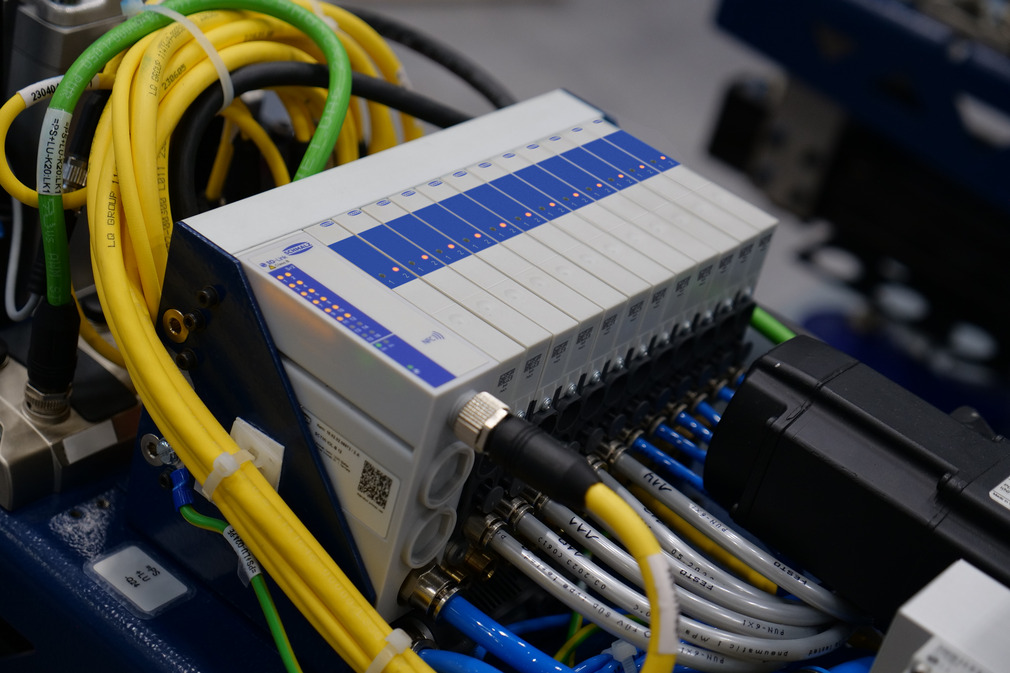

Compact terminals are powerful units for the generation, control and monitoring of vacuum in automated systems. Our mini compact terminal SCTMi is particularly compact and powerful, can control up to 16 separate vacuum circuits and can be quickly and easily integrated into the system. The intelligent IO-Link interface enables continuous monitoring of the terminal.

Complex sheet metal geometries on oily surfaces – our suction cups master sheet metal handling

The oval bellows suction cup SAOXB is optimally designed for handling elongated workpieces with oiled surfaces. With dimensions from 40 x 20 to 110 x 55 mm, it offers an extremely adaptable solution for optimum suction capacity on elongated sheet metal and car body parts. The special structured friction surface ensures maximum holding force at high accelerations, especially on elongated, oiled surfaces. The high stroke of the suction cup enables very good adaptation to different workpiece contours, while the flexible sealing lip provides a reliable seal even on curved, elongated workpiece surfaces. The bellows suction cup SAOXB is ideal for fast cycle times with sheet metal and body parts and masters even demanding handling tasks in automated sheet metal processing with maximum precision and reliability.

Vacuum handling

Highlights

Ergonomics and health protection are key issues for companies. With vacuum tube lifters and crane systems from Schmalz, you can make all processes involving the lifting and moving of sheet metal and metal plates particularly health-friendly, health protective and efficient.

Modular crane gantry KBG and vacuum lifting device VacuMaster Comfort - moving loads flexibly and safely

With the modular crane gantry KBG and the vacuum lifting device VacuMaster Comfort, Schmalz is focusing on the manual handling of large sheet metal. Using the vacuum lifting device VacuMaster Comfort suspended from the modular gantry, a single person can lift, rotate or swivel loads weighing up to 750 kilograms by up to 180 degrees. A controlled vacuum generator minimizes energy consumption and enables even handling of large and flat workpieces.

The Binar Handling Quick-Lift Arm QLA - Intelligent lifting aid for loads up to 300 kg

The Binar Handling Quick-Lift Arm QLA makes lifting and positioning workpieces weighing up to 300 kg much easier and particularly ergonomic. With the patented control handle, only minimal force is required to move loads precisely. Thanks to the 360° swivel range and integrated rotary joint, workpieces can be rotated continuously and positioned precisely.

The auto-balance mode enables intuitive operation directly at the workpiece, regardless of its weight. Low power consumption, high reliability and a long service life also ensure maximum efficiency in daily use.