Grip where it gets tricky: delicious rolls with a system

When all partners work together, the automation cell at automatica creates the perfect sandwich.

Robot specialist FANUC will be demonstrating what robots can do in combination with the right end effectors at its booth. The clever system places several ingredients on a bread roll without human assistance - just as the customer wishes. Indispensable for this: the flexible finger gripper mGrip from Schmalz. It grabs the sliced roll, a second finger gripper takes the underside and moves it to the mayonnaise station, then on to sausage, cheese, more mayo and salad. In combination with industrial slicers from Bizerba for the cold cuts, the precise dosing systems from ViscoTec and the user-friendly platform from KILIVATIONS, which orchestrates the processes, the perfect sandwich is created.

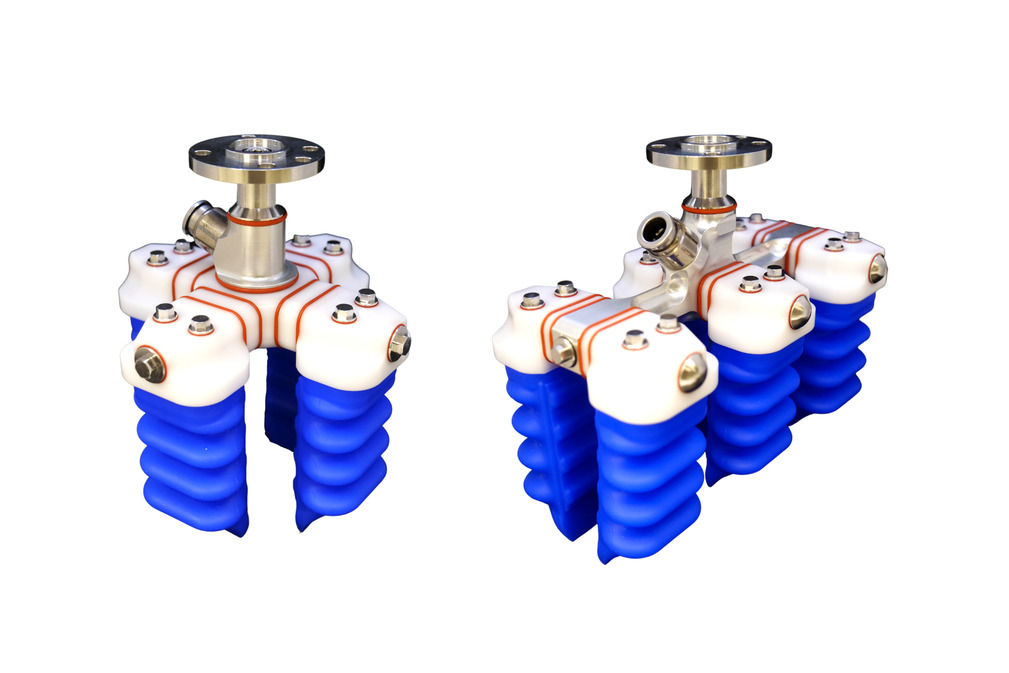

Finally, the flow gripper SCG uses air cushions to lift the delicate lettuce leaves and places them gently and precisely on the roll. This ensures reliable handling even when the suction area is only slightly occupied and with minimal surface pressure. The contact elements are food-safe and FDA-compliant. Thanks to the very high suction flow rate, they also grip porous and highly structured components with process reliability. The top lid, picked up again by the finger gripper mGrip, completes the composition and the gripper places the finished roll on the plate.

Gentle and adaptable

At the heart of the solution is the unique geometry of the finger gripper mGrip. It ensures a safe holder and adapts flexibly to the shape and properties of the products - nothing is squashed, nothing is deformed. The gripper is available in different sizes and is therefore suitable for any task. Thanks to hygienic design to degree of protection IP69K, the grippers can be used directly in food production. The open design minimizes the risk of contamination. The grippers are quick and easy to clean.

Sausage, cheese, salad - the finger gripper mGrip hands guests their individually topped sandwich.

A first finger gripper mGrip grips the bun, a second lifts the lid. Then it's time to add the ingredients.

The flow gripper SCG uses air cushions to lift the delicate lettuce leaves and places them on the sandwich.

Media contact

The Schmalz press team will be happy to answer any questions you may have.