Flat Suction Cups SUF

- Diameter: 1 to 100 mm

- Material: NBR, NBR-ESD, SI, SI-CO, HT1, HT1-ESD, EPDM-ECO

ESD (electrostatic discharge) refers to the sudden equalization of charge between objects with different electrical potentials.

In the electronics industry, workpieces are not only exposed to mechanical and thermal loads during manufacturing and handling processes, but also to the risk of electrostatic charges. This can result in voltages of several thousand volts. These can discharge uncontrollably and endanger components and parts.

Electrostatic charge is caused by friction, contact and routing processes. Materials such as plastics, textiles or metals store electrical charges that discharge suddenly when touched or approached. This process is particularly critical in the electronics industry, as even the smallest voltages can destroy sensitive components.

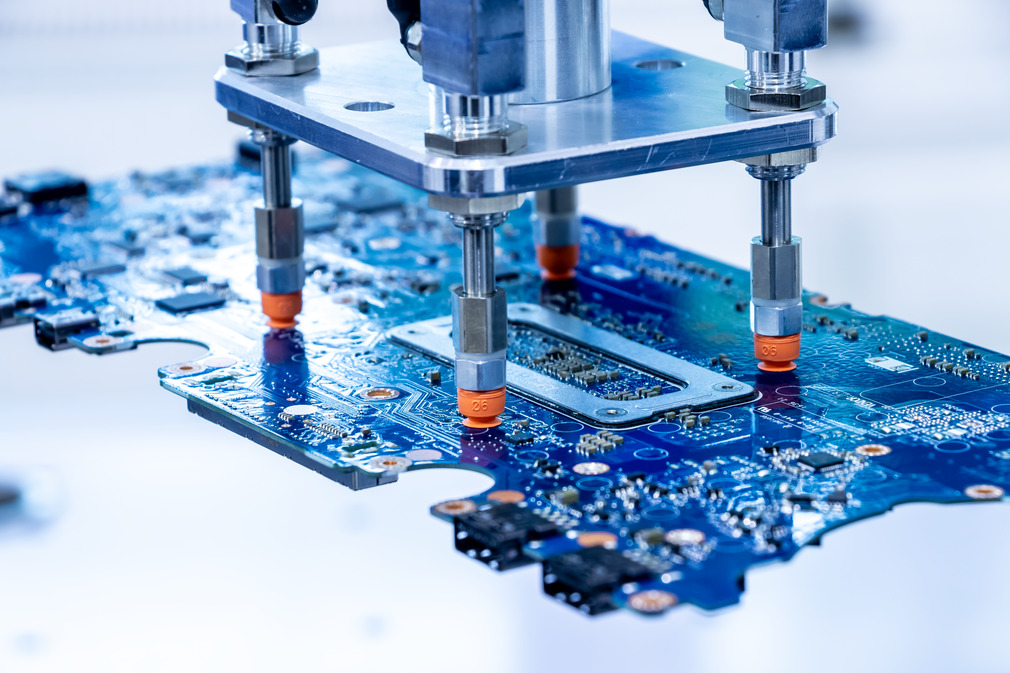

The consequences are often irreversible damage to electrical, electronic and optoelectronic components. Printed-circuit boards (PCBs) fitted with components such as metal-oxide-semiconductor field-effect transistors (MOSFETs) or insulated-gate bipolar transistors (IGBTs) are particularly susceptible. IC chips (integrated circuits) and substrates used in the semiconductor industry and electronics manufacturing are also at risk. Rapid equalization of the potentials causes high electrical voltages, which can lead to irreparable faults in assembled circuit boards and their sensitive individual components.

In order to effectively protect electronic components from ESD damage, for example during handling, the electrical conductivity of the materials used plays a central role. As these materials are in direct contact with the workpiece, they must ensure that electrostatic charges can be discharged in a controlled and damage-free way.

Electrical conductivity describes the ability of a material to safely discharge charges via its specific resistance. Depending on the resistance value, this happens either very quickly – as is the case with conductive materials – or in a delayed and controlled manner, as is typical for dissipative materials. The decisive factor here is always the specific resistance, which determines at what speed and in what way charges are safely discharged.

Depending on the material class, there are different specific resistance ranges:

The “point-to-ground” measurement is one particular means of verifying discharge capacity while taking the specific resistance into account. Based on this measurement, it is possible to identify the range in which the resistance of the overall system lies. With the aid of special resistance meters, the discharge resistance between a measuring point (1) and a grounding point of the system (ground potential) (2) can be established.

Sensitive Electronics Perfectly Handled – Minimized Marks, Maximized ESD Protection

In electronics manufacturing, there is no second chance. One tiny mark, one static discharge and entire batches are ruined. Not with us!

Our innovative suction cups made the material of HT1-ESD solve these challenges and many more: They protect workpieces from unwanted marks and ESD damage. With our suction cups, you benefit from:

Thanks to our extensive expertise in material development, the suction cup material HT1-ESD stands for cutting-edge technology and sets new standards in electronics manufacturing.

Suitable materials are often marked with the ESD protection symbol for better orientation. This symbol indicates that a product is suitable for ESD protection and reliably protects other components from electrostatic discharge.

To ensure that ESD protection is not only ensured at material level and in test procedures, but is also consistently implemented in the practical working environment, clearly defined areas with coordinated measures are required.

An ESD protection zone, or "EPA" for short (Electrostatic Protected Area), is a special working area in which all materials, tools and work equipment are designed to be electrically dissipative. This includes dissipative floors, earthing systems, ESD-compliant clothing and packaging. The aim is to prevent and discharge electrostatic charges in a controlled manner so that sensitive components such as printed-circuit boards, semiconductors or optoelectronic components are reliably protected.

ESD protection is essential in the electronics industry. Sensitive PCBs containing components like MOSFETs and IGBTs are highly vulnerable to electrostatic discharge and require reliable protection throughout all handling procedures.

ESD protection works by either preventing electrostatic charges or discharging them in a controlled way using suitable materials and earthing systems. The electrical conductivity of the materials used plays a central role in effectively protecting electronic components from ESD damage.

ESD protection is important because voltages of just a few hundred volts can be enough to damage electronic components. Without ESD measures, there is a risk of production downtime, quality problems and high costs due to complaints. Components are reliably protected with ESD-compliant materials and protection zones.

ESD protection is necessary wherever sensitive electronic components such as semiconductors, printed-circuit boards or sensors are processed, transported or stored. It prevents damage caused by uncontrolled discharges, especially in electronics manufacturing, laboratories and automated production processes.

ESD-capable refers to materials or products that can discharge electrostatic charges in a controlled and damage-free mway. This reliably protects sensitive electronic components from damage.

ESD packaging protects electronic components from electrostatic discharges during transportation and bearing. It consists of conductive or dissipative materials that discharge charges in a controlled way and at the same time shield sensitive components from outside electrical fields.

ESD material is tested using point-to-ground measurements. This involves measuring the electrical resistance between a defined point on the surface and the ground. This determines whether charges are safely and properly discharged in accordance with standards.

The central standard is IEC/DIN EN 61340-5-1, which specifies requirements for materials, workplaces and processes in electrostatic protection areas (EPA). There are also supplementary standards that specify additional requirements for test procedures and specific applications.