Schmalz at the K: Vacuum solutions for every type of plastics handling

From October 8 to 15, Schmalz will be exhibiting its vacuum solutions at the world's largest plastics trade fair, K in Düsseldorf (Hall 12, Stand 12 A35). Efficient automation technology and ergonomically designed handling systems meet the specific requirements of the industry - for example in hazardous areas.

Vacuum Automation

Highlights

Schmalz offers a comprehensive range of high-quality vacuum components that can be flexibly integrated into a wide variety of applications. From powerful grippers and precise connection elements to intelligent system monitoring components, filters and connections - at Schmalz you will find everything you need for your processes. In addition to individual components, Schmalz also offers complete systems, including ready-to-connect gripping systems that can be used in automated production, picking and distribution logistics environments.

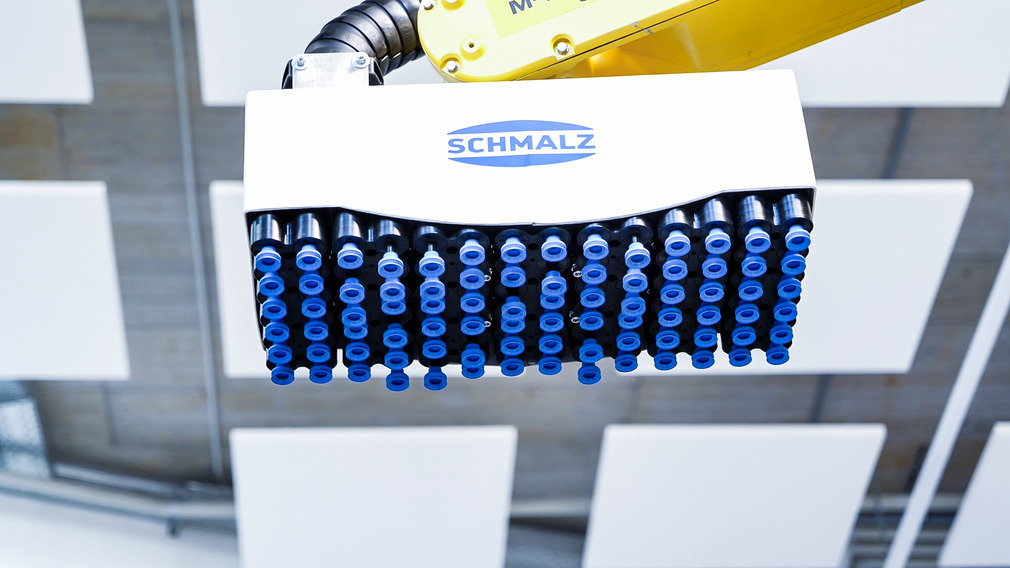

Flexible precision for efficient automation processes

The matrix area gripper FMG is the compact gripping module for maximum flexibility in automation. It enables the precise and fast handling of flat, predominantly air-tight workpieces in a wide variety of shapes and dimensions - from thin sheet metal to wooden boards. Thanks to individually controllable suction cups per module, several modules can also be combined to form a powerful area gripper and converted in seconds ( The integrated stroke prevents incorrect parts from being sucked in, while the low vacuum requirement and functional design ensure energy-efficient and simple integration. Whether in sheet metal or wood working, high-mix, low-volume processes or pick and place applications - the area gripper increases productivity and process reliability in equal measure.

Compact, robust, networked: The vacuum and pressure switch VS-V/VP-W-D

The vacuum and pressure switch VS-V/VP-W-D provides reliable measurement and monitoring of vacuum and overpressure in automation and handling systems. Its compact cube design, rugged glass-fiber reinforced housing, and IP65 protection make it ideal for industrial use in demanding environments—even with dust, dirt, and moisture. A 1-inch TFT display ensures clear visualization of measured values, while the IO-Link interface increases transparency, transfers process data directly to the control system, and helps minimize downtime. Thanks to its flexible mounting concept, the switch can be easily integrated directly on the suction cup, in the panel, or on a wall or DIN rail. This simplifies installation, saves time, and ensures a high level of process reliability.

Sustainable suction cup material EPDM-ECO

With the sustainable elastomer EPDM-ECO, Schmalz is focusing on environmental compatibility without compromising on power. The material, which consists of 90 percent renewable and recycled raw materials, offers the same resistance to weathering and ageing as previous solutions and is also resistant to acids, alkalis, vapors and alcohol. Ethylene propylene diene rubber (EPDM) does not contain any volatile pollutants and is durable. It is used in the SUF (flat suction cup) and FGA (bellows suction cup) series. Learn more at our booth.

Compact all-rounder for efficient vacuum control

The mini compact valve SCPM EV impresses with a maximum flow rate of 33 l/min and its particularly space-saving shape. It is ideal for use in vacuum systems - for example for controlling the gripper and for depositing workpieces and can be combined with both central electrical vacuum generators and (compact) ejectors. The automatic internal blow-off reduces the amount of wiring required, while integrated valve and sensor functions enable fast start of operations. The intelligent monitoring functions for evacuation time and leakage make the mini compact valve SCPM EV mini compact valve a reliable solution for modern systems with limited installation space.

The all-rounder for fast and efficient lifting of bags

Whether paper, plastic, or fabric bags – the new sack gripper PSSG from Schmalz offers a reliable and flexible solution for both manual and automated handling. Especially at the K trade show, the lightweight gripper showcases its strengths with bags of various materials and geometries, even when they are only partially filled. Its modular design enables easy integration and quick maintenance. The innovative sealing element ensures a long service life and prevents contamination caused by abrasion. Thanks to integrated NFC tags, spare parts and how-to videos are always at your fingertips. Ideal in combination with tube lifters such as JumboFlex and JumboErgo – for efficient processes in the plastics industry.

Manual handling

Highlights

With our innovative vacuum lifting devices and flexible, modular aluminum jib cranes, we offer custom-made solutions for manual handling in the plastics industry. Our devices are designed to significantly increase the efficiency and safety of your processes while enabling ergonomic handling. Visit us at the K trade show and experience live how our systems can simplify and optimize your work processes. See the quality, versatility and performance of our solutions for yourself.

Flexible transport with the vacuum tube lifter JumboFlex Mobile

The plastics industry needs flexible solutions for different production scenarios. The vacuum tube lifter JumboFlex Mobile masters this challenge thanks to its transportable design and enables the ergonomic handling of workpieces weighing up to 50 kg - ideal for changing locations. Thanks to its compact transport dimensions and height-adjustable column, it is quickly ready for use, whether temporarily or permanently, for example for machine loading. The quiet operation at 400 V mains voltage ensures efficient and flexible support in your production.

More simple. More efficient. More ergonomic

The vacuum tube lifter JumboFlex enables workpieces weighing up to 50 kg to be moved ergonomically and quickly - also ideal for plastics and plastic sheets. The intuitive two-button control ensures effortless lifting, lowering and hovering at any height with minimal training time. Gripper changes are twice as fast and effortless, while the optional swivelling function supports the backward swivelling and continuously rotating of workpieces. The JumboFlex thus increases cycle frequencies and ensures gentle, efficient processes in logistics, production and plastics processing.

Safe handling in explosion-protected areas

The vacuum tube lifter JumboSprint EX moves compact workpieces weighing up to 250 kg safely and effortlessly - even in potentially explosive atmospheres. Whether bags, barrels, buckets or jugs: the all-round bow-shapped operator handle ensures precise guidance and ergonomic working. Thanks to its modular design and wide range of accessories, the vacuum tube lifter JumboSprint EX can be flexibly adapted to any application. Certified in accordance with ATEX Directive 2014/34/EU, it can be used throughout Europe without additional certificates