Our solution can handle 31,000 chips per hour. Crucial components such as the robot and the gripper ensure reliable, trouble-free continuous operation.∼ Jochen Erler, Managing Director erler gmbh automation . robotics.

Schmalz Suction Cups for Fast PCB handling

Erler gmbH automation . robotic has developed an innovative robot cell for Schweizer Electronic AG that specializes in the automated handling of small semiconductor components. In this cell, a Stäubli Scara robot takes on the task of placing up to 31,000 chips per hour from a standard tray into a special holder for the subsequent etching bath. This precise and efficient handling is made possible by 176 flat suction cups from Schmalz.

Characteristics of the success story

| Industry | Electronics |

|---|---|

| Workpiece | Semiconductor components |

| Product group | Vacuum Components |

| Type of handling | Automated handling |

With Schmalz

31.000

chips

per hour

The Customer: Erler gmbh automation . robotics

The Swabian family business erler gmbh automation . robotik, based in Dormettingen in the Zollernalb district, operates in the industrial automation and robotics sector. Since its foundation in 1995, the company has developed into a full-service provider for control technology and has focused on robotics since 1998. With over 200 successfully implemented robot control systems, Erler GmbH has played a significant role in securing the future of many companies in Baden-Württemberg. The company currently employs 47 people working in process engineering, factory automation, and machine technology.

The Challenge

erler gmbH automation . robotik has developed a robot cell for its customer, Schweizer Electronic AG, which handles semiconductor components, particularly semiconductor chips. These chips are crucial for the power of electrical drives and assistance systems. Schweizer Electronic was looking for an automated handling solution for these sensitive semiconductor chips. The challenge lies in the process of printed-circuit board embedding, in which the chips are embedded in copper inlays. Prior to this, the copper surfaces of the chips must be roughened in an etching bath. Therefore, a solution was required to safely transfer the chips from a standard tray to a special device for the etching bath. Schmalz was responsible for the end-of-arm tooling of the robot and developed a gripper for handling the sensitive semiconductor components.

Schmalz's Solution

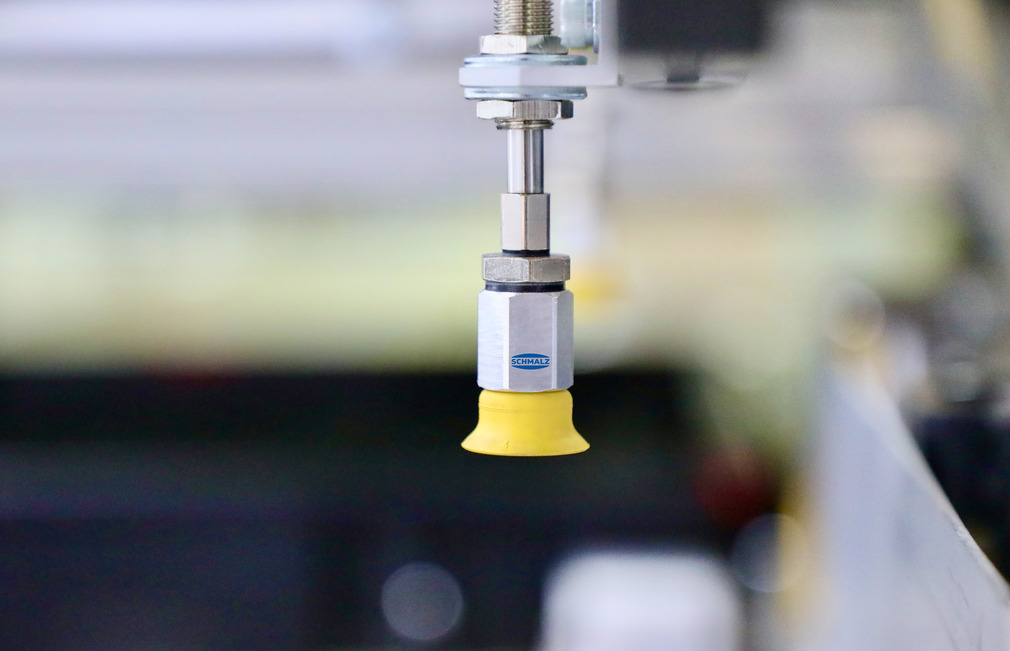

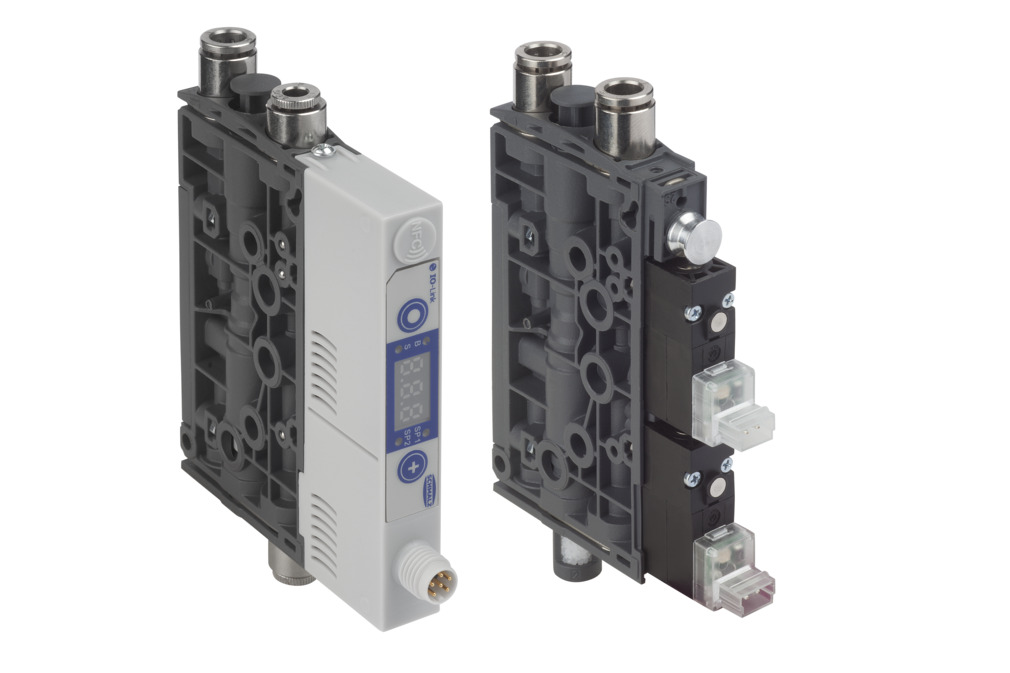

The gripper developed by Schmalz is perfectly adapted to the handling of semiconductor components in a robot cell. It removes the chips from the tray and places them precisely in the special holder for the etching bath. With a size of 320 x 140 millimetres and a weight of just 2.5 kilograms due to its aluminum base body, the gripper is easy to assemble and integrate into the robot system. The gripper is equipped with a prefabricated flange mount to simplify installation. The special feature of this gripper is the 176 flat suction cups from Schmalz, which enable the precise and reliable handling of the semiconductor components. Due to their geometry, the flat suction grippers move only minimally in an axial direction and are designed to pick up the workpieces cleanly and set them down again precisely without tilting. The flat suction cups have a diameter of six millimetres and are made of NBR-ESD nitrile rubber. They reliably protect sensitive components from uncontrolled electrostatic discharge and are also extremely resistant to chemicals. In addition, further suction cups with flexible spring plungers and independent vacuum generation were installed at one point in the system. These are responsible for removing the lids before the SE trays are loaded or unloaded, and for transporting the trays to the transfer station. The vacuum in the gripper is generated by an IO-Link compatible compact ejector of the SCPMi type installed in the system. This enables efficient vacuum generation and is also particularly energy-saving thanks to the integrated air saving function, which reduces compressed air consumption.