Vacuum End Effector VEE Configuration Concept

Vacuum End Effector VEE

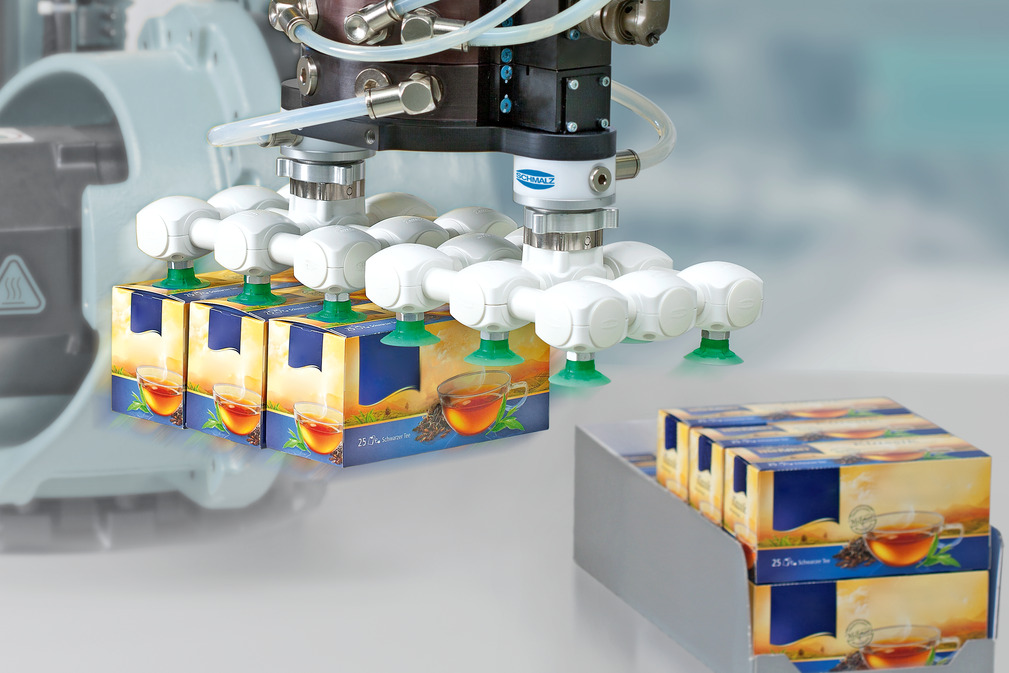

The vacuum end effector VEE describes a complete gripping system for use in fast pick & place processes in the packaging industry.

In connection with delta and scara robots, the vacuum end effectors realize the shortest cycle times. The end effectors are designed for use in primary and secondary packaging processes. For example, for the automated filling of cardboard boxes in case packers or for applications in toploading machines and in case and tray erectors. Thanks to the quick-change adapters, the vacuum end effectors are ideal for use in flexible packaging machines with frequent format changes.

The vacuum end effector is based on a modular system. This enables quick and cost-effective configuration.

Design of a Vacuum End Effector VEE

The Vacuum End Effectors VEE can be assembled from coordinated modular elements. During configuration, the number of suction points and the distances between the suction points can be variably changed. This allows the end effector to be optimally adapted to the workpiece dimensions. The large selection of suction cup types optimizes the end effector for a wide range of applications.

Schmalz recommends the design of vacuum end effectors VEE within the following framework:

- Max. Workpiece dimensions: 400x300 mm

- Max. Workpiece weight: 2,000 g

- Max. Number of suction pads: 12

- Max. Max. size of vacuum end effector: 350x250 mm

Basic elements in the modular system

The VEE modular system consists of a large number of components that can be combined with each other. The following components are required for the design:

Flange plates

- Type-specific flange plates and universal flange plate for connecting the vacuum end effector to the robot

- Screws for mounting to the vacuum end effector included

Flange modules

- Manual quick-change adapter with bayonet lock including vacuum connection; tool-free connection to the basic module

- With vertical and horizontal vacuum connection

- Nominal flow 20 m³/h or 60 m³/h

Basic modules

- Basic component for the design of a vacuum end effector

- Tool-free connection to the flange module using a bayonet lock

- Central vacuum feed

Suction cup

- Almost all suction cups from the Schmalz product range can be used.

Information on the layouts of the End Effector

In principle, the VEE modular system can be used to create any variant of an end effector. In each layout, the connection to the robot is at the center of the vacuum end effector (indicated by the black dot in the 2D sketches). The end effectors are all symmetrically designed.

We currently distinguish between five basic types of these preconfigured vacuum end effectors:

1. Layouts that only consist of a basic module (VEE-QCF)

2. Layouts with a variable length dimension

3. Layouts with two variable lengths

4. Layouts with two variable length dimensions and a somewhat more complex design

5. Layouts with three variable length dimensions

Depending on the requirements, workpiece layout, workpiece weight, transport speed, etc., it is determined which of the layouts is most suitable. This layout can then be adapted accordingly.

Information on workpiece definition

The Vacuum End Effector can hold several workpieces in one picking process.

Definition of the workpiece position:

Total length of all workpieces L [mm]: All workpieces in a pick process, including the distance between the individual workpieces, make up the total length. This must not exceed 400 mm.

Total width of all workpieces B [mm]: All workpieces of a picking process including the distance between the individual workpieces result in the total width. This must not exceed 300 mm.

Total weight of all workpieces [g]: All workpieces in a picking process must not exceed the maximum total weight of 2,000 g.

Example 1:

Workpiece layout with 4 workpieces and selected layout 4

Example 2:

Workpiece distribution with 4 workpieces and selected layout 6

Care should be taken to ensure that the workpieces are distributed as evenly as possible under the individual suction cups. The placement can be influenced by changing the length dimensions (L1, L2).

Length adjustment of the Vacuum End Effector:

The following example of layout 8 shows the influence of adapting the length dimensions on the vacuum end effector:

Characteristics 1:

L1: 50 mm

L2: 100 mm

Characteristics 2:

L1: 100 mm

L2: 100 mm

Information on the suction cups

The Vacuum End Effectors VEE are preferably used in the packaging sector and, thanks to their features, are ideally suited to the requirements of packaging processes. Below are 6 different suction cup types that are particularly suitable for handling packaging. Our product range includes a variety of other suction cups that can be used in combination with the VEE.

Examples: Bags and flexible packaging

Type SPB2f suction cups: The bellows suction cups made of FDA-compliant silicone are suitable for handling bags even with heavy wrinkling, a low fill level or swivel movements during the handling process thanks to the flexible and adaptable sealing lip. Thanks to the integrated support, even thin and soft plastic films (LDPE) are not pulled in. The suction cups are available in diameters of 30 mm to 50 mm.

Type SPB4f suction cups: The bellows suction cups made of FDA-compliant silicone are suitable for handling bags even with heavy wrinkling, a low fill level or swivel movements during the handling process thanks to their flexible and adaptable sealing lip. Thanks to the integrated support, even thin and soft plastic films (LDPE) are not pulled in. The suction cups are available in diameters of 30 mm to 50 mm

Type SPB4 suction cups: The bellows suction cups made of fda-compliant silicone are particularly suitable for handling dimensionally unstable packaging such as bags and plastic films thanks to their reinforcing shape and soft sealing lip. The suction cups are available in diameters of 20 mm to 50 mm.

Cardboard and stable packaging:

Type SPF suction cups: The flat suction cups made of the special material Elastodur with support ribs, reinforced main body, flexible sealing lip and low inside volume are particularly suitable for handling rigid packaging such as cardboard.

Type SPB1 suction cups: The bellows suction cups made of the special material Elastodur are particularly suitable for handling rigid packaging such as cardboard due to their reinforcing main body, high stroke and damping effect. The suction pads are available in diameters of 10 mm to 60 mm.

Type SPB2 suction cups: The bellows suction cups made of the special material Elastodur are particularly suitable for handling rigid packaging such as cardboard due to their flexible and adaptable sealing lip and high stroke. The suction cups are available in diameters of 20 mm to 50 mm.

Information on the vacuum module

The vacuum modules enable energy-efficient pneumatic and electrical vacuum generation directly on the gripper. The pneumatic vacuum modules are characterized by a high suction capacity with low air consumption and guarantee a quick and tool-free change thanks to the bayonet lock, as well as quick and easy cleaning of the vacuum end effector.

The electrical CobotPump vacuum modules only require a power or data cable for operation. A vacuum or compressed air hose from robot to vacuum module is not required.

Pneumatic modules with different nozzle sizes, each with/without silencer:

- VEE-QCMV HF 2 13 22 SD with ecoPump SEP nozzle 1.3 mm and silencer

- VEE-QCMV HF 2 13 22 with ecoPump SEP nozzle 1.3 mm without silencer

- VEE-QCMV HV 2 07 13 with ecoPump SEP nozzle 0.7 mm without silencer

- VEE-QCMV HV 2 07 13 SD with ecoPump SEP nozzle 0.7 mm and silencer

Electrical modules (CobotPump):

- ECBPi 12 24V-DC M12-8, CobotPump with plug connection M12-8

- ECBPi 12 24V-DC TB-8, CobotPump with terminal strip connector

Information on the flange plate

The flange plates are used to connect the vacuum end effector to the robot. Various flange plates are available. Our experienced system consultants will be happy to assist you if you cannot find the flange plate you require.

Flange plates for pneumatics vacuum modules

| Type | Part number | For robot type | Weight [kg] |

|---|---|---|---|

| FLAN-PL 63x11.5-UNI | 10.01.30.00017 | Universal flange for post-processing (customized solutions) | 0,068 |

| FLAN-PL 55x7.5-AB1 | 10.01.30.00015 | ABB IRB 360 Flexpicker (outside IRB 360-6/1600) Fanuc Parallel Link M-1iA Fanuc M-2iA |

0,037 |

| FLAN-PL 63x10.5-AD1 | 10.01.30.00016 | ADEPT QUATTRO s650 | 0,065 |

| FLAN-PL 55x9.5-JP1 | 10.01.30.00194 |

Fanuc M-3iA, CR-4iA, CR-7iA, CR-15iA, CR-35iA |

0,035 |

| FLAN-PL-55x7.5-EL1 | 10.01.30.00208 | Elau (Schneider Electric) Robot P4 | 0,048 |

| FLAN-PL 80x9-ST1 | 10.01.30.00167 | Stäubli TS40, TS60 and TS80 | 0,130 |

| FLAN-PL 63.5x10 AL-EL VEE | 10.01.30.00806 | Universal Robots UR 3, 5, 10 Kuka iiwa 7, 14 |

0,060 |

Flange plates for electrical vacuum modules

| Type | Part number | For robot type | Weight (kg) |

|---|---|---|---|

| FLAN-PL-UR-KUK-1 | 10.03.01.00313 | Universal Robots UR 3, 5, 10 | 0,08 |

| KUKA iiwa 7, 14 | |||

| AUBO i3, i7, i10 | |||

| MABI SPEEDY 6, SPEEDY 12 | |||

| Stäubli TX290, RX160 (only for ECBPi) | |||

| FLAN-PL-RET-1 | 10.03.01.00358 | Rethink Robotics - Saywer model (without ClickSmart adapter) | 0,1 |

| FLAN-PL-RET-2 | 10.03.01.00373 | Rethink Robotics - Saywer model (with ClickSmart adapter) | 0,09 |

| FLAN-PL-FAN-1 | 10.03.01.00390 | FANUC CR-4iA, CR-7iA, CR-7iA/L | 0,14 |

| KAWASAKI duAro2 | |||

| MITSUBISHI Melfa RV-2FRL(B), RV-4FRLM, RV-7FRM, RV-7FRLM, RV-7FRLLM | |||

| OMRON Viper 650, Viper 850 (articulated robots) | |||

| FLAN-PL-FAN-2 | 10.03.01.00518 | FANUC CR15iA | 0,19 |

| FLAN-PL-YAS-2 | 10.03.01.00404 | YASKAWA Motoman HC10 | 0,22 |

| FLAN-PL-YAS-3 | 10.03.01.00471 | YASKAWA Motoman HC10DT | 0,25 |

| FLAN-PL-ECBPI | 10.03.01.00379 | Universal connection with G1/4" female thread, which is mounted on the underside of the ECBPi (suction side) | 0,23 |

Information on the flange module

The flange modules enable operation of the vacuum end effector with multi-stage ejectors (multi-stage venturi nozzles) or side-channel compressors. The interchangeable adapter with bayonet lock guarantees quick, tool-free replacement of the vacuum end effector. Three different flange modules with different nominal flows are available:

- VEE-QCM 30 with nominal flow 60 m³/h for vertical vacuum feed

- VEE-QCM 51 with nominal flow 20 m³/h for horizontal vacuum feed

- VEE-QCM 65 with nominal flow 60 m³/h for horizontal vacuum feed

Information on the flange extension

The flange extensions offer the option of dipping into cardboard boxes, boxes or crates. Here too, the interchangeable adapter with bayonet lock forms the interface to the vacuum end effector.

Three different flange extensions with different lengths are available:

- VEE-FE 25.4x79.5 with an overall length of 79.5 mm

- VEE-FE 25.4x129.5 with an overall length of 129.5 mm

- VEE-FE 25.4x179.5 with an overall length of 179.5 mm

Information on the blow-off valve

In automated applications, blow-off pulses can be applied to the vacuum end effector via a solenoid valve to quickly deposit the workpiece.

Information on the Blow-Off Valve

With a solenoid valve you can give a blow-off impulse to quickly release the workpiece in an automated application.

Additional Options in the Product Configurator

The configurator allows you to configure an appropriate end effector for each specific workpiece geometry and/or workpiece layer. The configuration is displayed as a 3D model.

The following additional options are available in the configurator:

- “Hide workpiece”:

Display of the 3D model without the workpiece, so the bottom of the end effector can also be viewed. - Configuration without suction cups:

If suction cups that are not available in the configurator are to be used for the vacuum end effector, the option “Configuration without suction cups” can be selected. - Stabilizer element:Stabilizer elements are available for suction cups SPB4-30 and SPB4-40. These elements can be taken into account in the configuration by selecting the option “Stabilizer element”.

Information on the Configuration Result

After the configuration of the end effector, the configurator provides the following:

- 3D CAD model

- 3D PDF document

- Detailed parts list

- Option for requesting the modular system elements for assembling the end effector from Schmalz

Disclaimer

J. Schmalz GmbH, as a supplier and manufacturer of vacuum technology, takes no responsibility for the functioning of vacuum end effectors VEE in a specific process.

Any replacement of suction cups necessitated by a change in cup size, the addition of suction cups or the modification of the VEE configuration to optimize functioning is not the responsibility of J. Schmalz GmbH.

Changes to the packaging material, the goods which are packaged, the fill level or the air content in the packaging influence the entire handling process and the behavior of the workpieces.

We reserve the right to make technical changes to the products or to develop them further at any time.

The configurator does not perform a plausibility check regarding the combination of the workpiece and the selected configuration of the vacuum end effector.

Contact

Velika Ligojna 4

Vrhnika

.jpg)

.jpg)

.jpg)