Digital Engineering

Digital planning, smarter development, sustainable production. Experience how the classic art of engineering and state-of-the-art digital technologies come together - with digital engineering solutions from Schmalz.

Unplanned downtime, loss of productivity, rising costs - often caused by incorrect design, inadequate testing or unsuitable product design. This is a daily reality in automation.

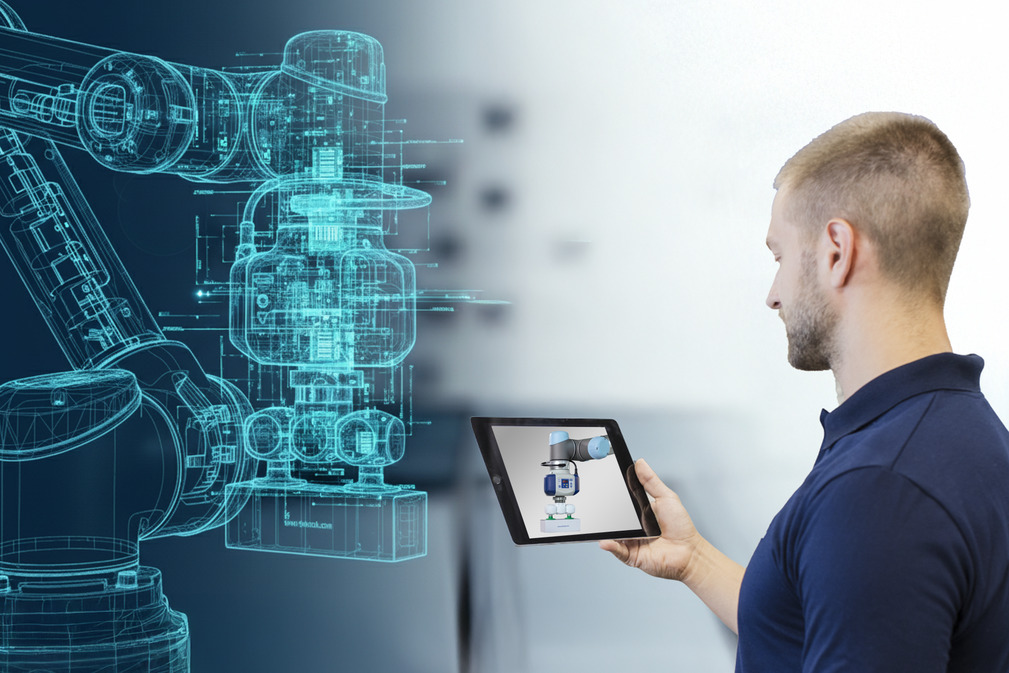

But what if systems could be planned, tested and optimized virtually before they even existed? Digital models, simulations and AI methods can be used to compare variants, analyze performance data and perfect designs - long before the first prototype is created.

This is digital engineering: a continuous, data-driven process across the entire product life cycle - from design and configuration to operation. Schmalz combines decades of engineering expertise with digital technologies and already offers solutions that support you from the initial idea to the optimal product design.

Design processes are reduced from weeks to days - thanks to the digital design of your gripping solution.

Simulations, digital twins and intelligent selection aids ensure that the solution is precisely tailored to your production processes.

Precise design means you avoid oversizing, prevent expensive production downtime and reduce material and energy costs.

100% self-service, 0% waiting time - changes or variants can be checked and implemented digitally in minutes.

Speed is crucial in automation. Digital engineering gives you a competitive edge in the design process - through intelligent planning and demand-optimized design.∼ Patricia Heinzig, Manager Product Digitalization

Our vision

We invest in digital twins, realistic simulations and intelligent engineering tools. Our aim is to offer you a networked, digital world in which you can plan your projects with foresight, implement them efficiently and continuously optimize them.

Already a reality today

Schmalz's digital solutions already provide you with powerful tools. They allow you to plan, configure and dimension systems quickly, precisely and intuitively.

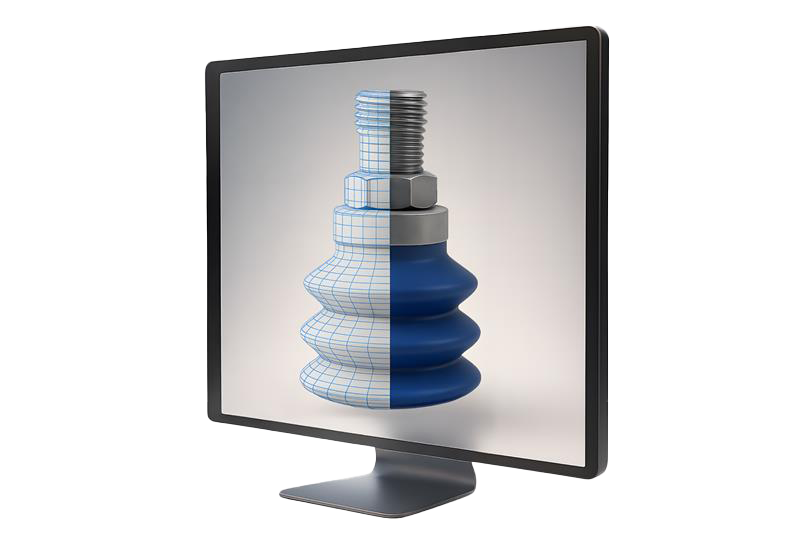

Digital twins - digital images of real products - are at the heart of the digital factory. They also play a central role at Schmalz: jib users can use intelligent CAD models to optimally design their gripping system as early as the design phase. The twin provides all the necessary data and parameters - virtually and in real time.

Simulations make it possible to experience complex processes virtually - without expensive prototypes or time-consuming tests. The entire system is digitally simulated, including all interactions. This allows systems, processes and products to be examined and optimized under different conditions.

At Schmalz, simulations are an integral part of the digital engineering process. We take care of this for you and create transparency across your entire system. We answer key questions such as: How lengthy are the evacuation times? How high is the air consumption? Does the design match the entire system? This allows you to identify potential errors before planning and the start of operations and ensures that the design and processes are optimal from the outset. For you, this means lower costs, stable processes and sustainably efficient production.

From CAD file to digitally designed gripping solution: Schmalz automates sheet metal handling

How can digital design, flexible gripping systems and ergonomic handling solutions make sheet metal processing more efficient? Answers to these questions can be found at Blechexpo (October 21 to 24, Stuttgart) in Hall 1 at Stand 1110 at vacuum specialist Schmalz.

New

FQE-V gripper system: independent of size and shape

With the new FQE-V, Schmalz has developed a modular, freely scalable gripper system for robotics. It enables workpieces of different sizes and shapes to be handled safely. Applications benefit from particularly fast project planning.

Configuring spring plungers made easy

The FSTIm and FSTImc spring plungers can be individually adapted to different requirements. This provides companies with custom-made solutions for their plant automation. Schmalz offers a new online configurator with integrated error prevention to make the design process quick and easy.

Simply automate

In automation, different systems and technologies work hand in hand. Integrators must be sure that all components work together smoothly and can exchange data and information seamlessly. Schmalz supports them in this with software modules, online tools, smart products and vacuum know-how - from the conception to the running process.

Johannes-Schmalz-Str.1

72293 Glatten

Germany