Since we have been clamping with vacuum, we no longer have any damaged sheets.∼ Sebastian Burster, Team Leader Programming, SiSS GmbH

Schmalz Vacuum Fixation for CNC Machining

Vacuum fixes sensitive plastic sheets evenly and firmly to the base. Precision and the gentle distribution of the clamping force characterize this innovative process. Thanks to the vacuum clamping system from Schmalz, the manufacturing service provider SiSS is now finally producing plastics elements reliably and efficiently.

Characteristics of the success story

| Industry | Manufacturing services |

|---|---|

| Workpiece | Plastic sheets |

| Product group | Vacuum Clamping Technology |

| Type of handling | Clamping |

With Schmalz

90

percent

less set-up time

The Customer: SiSS GmbH

SiSS produces complex components and systems for various industries in Baden-Baden Steinbach. In addition to components for medical technology, the 65 employees manufacture solutions for charging infrastructure, refrigeration and railroad technology on an area of around 18,000 square meters. The wide range of production methods includes machining, welding and laser technology, sheet metal forming, powder coating and surface treatment. The company has an eventful history behind it: SiSS emerged from Medifa GmbH in November 2023, which had to file for insolvency in the fall of 2022. Last year, Weinmann Aach AG took over the production site and continues to run it under the name SiSS (Solutions in Style, Steinbach). Weinmann Aach is a provider of metal solutions and has 50,000 square meters of storage space, where a wide range of sections, pipes, rods, beams, sheet metal and sheets are kept in stock.

The Challenge

SiSS manufactures plastic parts made of PVC, PTFE and acrylic glass on a CNC machining center. The challenge was to manufacture small, different milled parts in series. The company used a hydraulic vice to hold the parts in place on the worktop. This repeatedly resulted in damage to the plastic components, which were literally pressed together by the vice. This led to a large amount of waste and faulty processes.

Schmalz's Solution

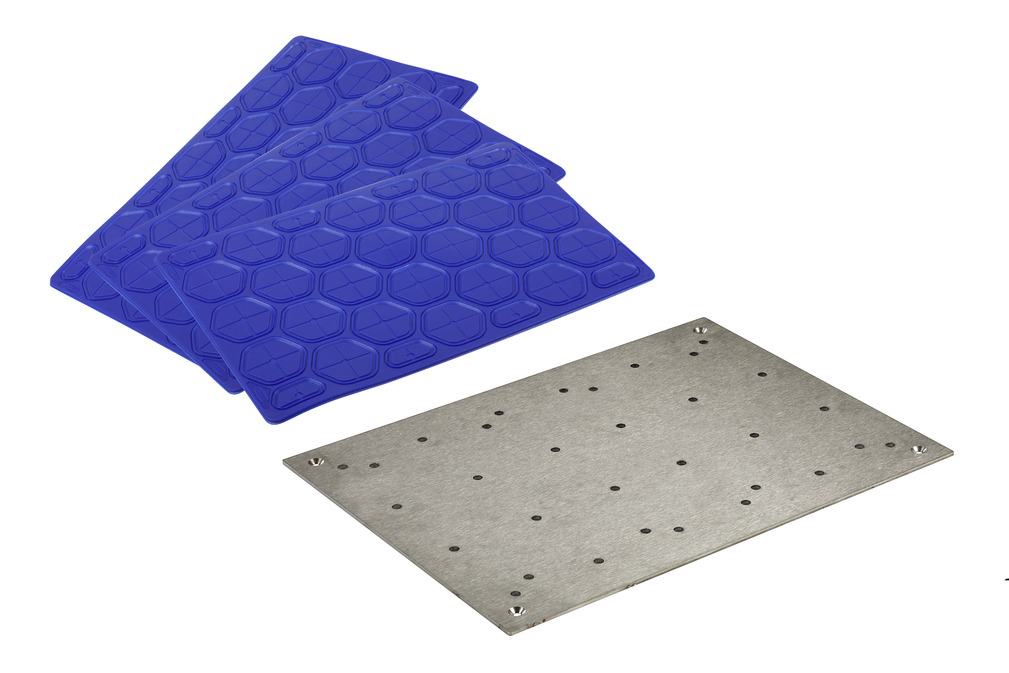

The MPL 600×400×28 Matrix-Plate is made of aluminum and has milled slots in which air-tight workpieces can be fixed directly with vacuum. The flat holding force of this sheet fixes the component with little tension and is particularly suitable for soft and thin products. A milled grid distributes the vacuum evenly over the surface, while a sealing gasket limits the evacuated space. The Matrix-Plate carries the Innospann Steel-Plate (ISST) clamping system from SiSS. This three millimetre thick sheet made of magnetic, corrosion-resistant steel has regularly arranged vacuum holes with a diameter of seven millimetres. Applications can supply the clamping equipment with vacuum using either Innospann vacuum blocks or a FlexMat, as currently used by SiSS. The FlexMat SFM elastomer mat fixes the plastic sheets directly, enables openings to be made and workpiece edges to be machined. With nubs on the underside, it grips safely into the holes in the Innospann Steel-Plate and directs the vacuum upwards into 32 separate suction cells. The mat is designed as a wear item and can be reused several times as long as it remains undamaged. The EVE-TR-40-AC3-F vacuum pump in dry-running version achieves the required vacuum with low power consumption and is suitable for economical continuous operation. At SiSS, a specialist manually loads the machine with the raw plastics sheet. The vacuum can then be opened directly at the machine table using a manual slide valve. The gauge allows the employees to keep an eye on the vacuum at all times. The workpieces sit firmly on the workbench without being damaged. After the milling process, the finished sheets are removed manually and the workpieces are released and deburred. The new clamping system not only saves costs by reducing waste. SiSS now works reliably and significantly faster than before. The accuracy and quality of the machined parts have also improved.