End-of-Arm Tooling (EOAT)

Safe and efficient processes in industry and logistics with EOAT from Schmalz.

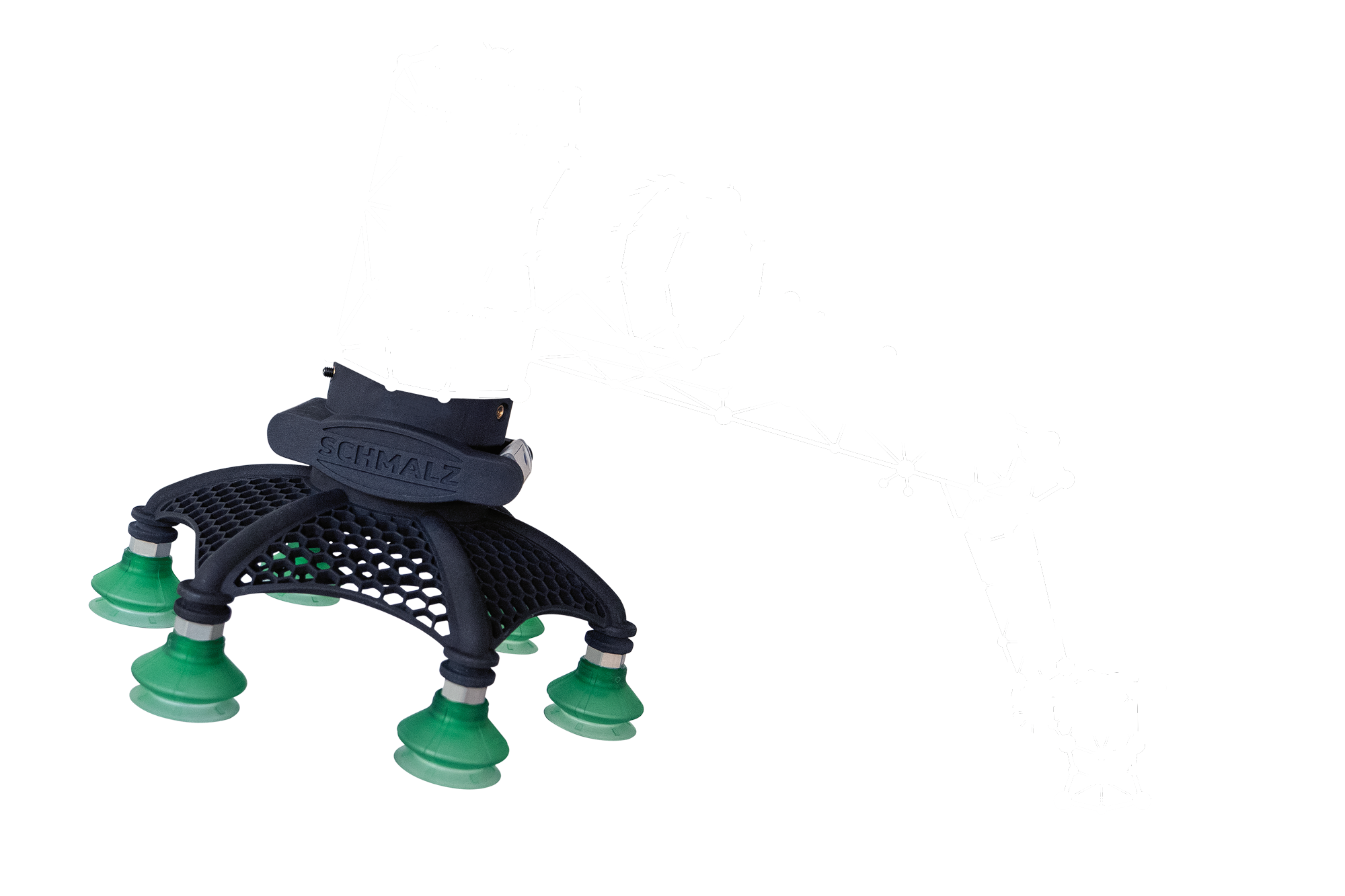

End-of-arm tooling (EOAT) are the specialized tools mounted at the end of robotic arms and other automation systems that grip, move and position workpieces. They increase productivity, reduce process costs and are key components in modern automation and handling applications.

Products from Schmalz ensure maximum precision, safety and process control. This enables you to implement automated workflows efficiently and continuously optimize them.

Schmalz cooperates with leading robot manufacturers to develop customized EOATs. Our ready-to-connect handling sets are tailored to your applications and production processes, featuring not only the gripper but also the matching flange and connection cables.

Industry knowledge, success stories and application videos for your automation solutions.

Selection aids, configurators and the Schmalz Calculator for simple, efficient process planning.

Schmalz stands for customer proximity, reliable consultation and know-how.

With EOAT, we connect robots and workpieces – and thus create the basis for productivity, ergonomics and cost efficiency in automation.∼ Dr. Maik Fiedler (Member of the Management Board and Head of the business unit Vacuum Automation)

An EOAT system consists of several components that work together to ensure the handling of workpieces. The robot (1) serves as the base and performs the movements. The robot is connected to the vacuum generator (3) via the flange (2) and generates the necessary vacuum. Below this is the vacuum gripper (4), shown here as an example with suction cups that securely pick up the workpiece (5). The system is controlled via an operator panel (6), while the software (app) (7) is used for programming and adjusting the system.

Discover practical videos that show gripping systems from Schmalz in action. Our EOAT solutions use real applications to demonstrate how you can automate your applications efficiently and handle a wide variety of workpieces safely.

The flexibility of EOAT solutions is crucial for companies that need to respond to changing production requirements. Vacuum grippers are not limited to a single activity, but can be adapted in many ways to different applications and varying workpieces.

Whether you want to handle workpieces with vacuum, magnetically or mechanically: Schmalz offers individual components, ready-to-connect sets and complete gripping systems for your application.

Our modular solutions can be quickly integrated into existing systems and are scalable for different batch sizes. From selection to the start of operations, we support you with technical consultation and practical function tests to ensure that your process works reliably.

EOAT is the key to flexible automation

Dr. Maik Fiedler is a member of the company management and head of the Vacuum Automation business unit at Schmalz. In this interview, he explains the strategic importance of End of Arm Tooling (EOAT) for automation and describes how Schmalz designs the connection between robot and workpiece.

New

Schmalz matrix area gripper FMG named "Product of the Year 2025"

The readers of the trade magazine Industrial Production have decided: INDUSTRIAL Production presented 47 nominees at the end of the year. Schmalz came out on top in the material handling category with the matrix area gripper FMG and won first place. The award ceremony took place on February 27 in Darmstadt and brought together leading industry representatives.

Portfolio expanded: Schmalz takes over finger gripper from Soft Robotics Inc.

The vacuum specialist Schmalz is expanding its gripper portfolio: As of August 5, the family-owned company from Glatten will acquire the mGrip product family from the US company Soft Robotics (SRI), including all finger gripper configurations, patents and the associated know-how. Schmalz is thus expanding its market position in the food product handling sector.

Configure PXT gripper by yourself now

Schmalz has launched their new configurator: Since the beginning of May, customers are able to directly design a gripper suitable for their application based on the PXT modular gripper system - around the clock. The vacuum expert is expanding its digital services with the new online tool.

End-of-arm tooling (EOAT) from Schmalz enables the precise and safe implementation of intelligent automation solutions. The combination of specific vacuum components and gripping systems creates highly efficient complete systems that offer maximum flexibility in various applications. Our focus is on powerful and user-friendly vacuum technology that offers you numerous advantages:

Robotics solutions from Schmalz are used for loading and unloading machines, for picking, palletizing and depalletizing or for bin picking processes. The range includes standardized and configurable end effectors, modular gripper systems, vision & handling sets as well as electrical and pneumatic vacuum generators.

Our gripper solutions are compatible with all common lightweight robots and cobots and are provided as ready to connect sets. Equipped with communication interfaces for bidirectional data exchange, with diagnostic functions for the handling process, with vision systems for gripping point detection or ecosystems for automated gripper change, the gripper plays a central role in the overall system.

In this handling application, the EOAT takes over the picking and placing of the workpieces. It picks them up from a defined location and places them at another, equally defined position.

Thanks to high precision and repeatability, the EOAT can reliably perform such tasks around the clock. Recurring tasks can be easily programmed, saved and retrieved at any time.

A particularly demanding variant is the so-called "bin picking". In this case, a camera system identifies the respective component, allowing the EOAT to remove it independently from the bin. In combination with a cobot, this creates a flexible solution for automated pick-and-place processes.

EOAT systems provide optimal relief to skilled employees by automating monotonous machine loading and unloading. What's more, because cobots with EOAT are constantly available and can operate day and night, machine idle times are substantially reduced. As soon as processing is complete, the EOAT immediately unloads the machine and reloads it with new parts. Cobots do not require much space for this, and manual operators can still operate the machines. Equipped with vacuum grippers, EOAT systems offer exceptional flexibility and can handle various workpieces across different machines.

The vacuum gripper moves even soft and delicate materials and irregular shapes safely and gently. Once the product quantity and the respective target position have been saved, the parts are systematically placed until the cardboard box is full. The finished packaged parts are neatly stacked on the pallets in positions specified by humans.

The vacuum gripper of the EOAT handles the parts with minimized marks and positions them precisely in the specified position for analysis or testing processes. The parts are inspected or processed by the machine. Once the process is complete, the cobot is informed. During inspection processes, the cobot receives a signal indicating whether the inspected part should be forwarded for further processing or sorted out.

The vacuum gripper of the EOAT picks up the workpieces from above and reliably places them in the desired position. The individual components are gripped and assembled one after the other. Once saved, the work steps can be repeated as often as required. Without spatial separation, the vacuum grippers take over monotonous tasks. Humans monitor, control and supervise the processes.

Johannes-Schmalz-Str.1

72293 Glatten

Germany