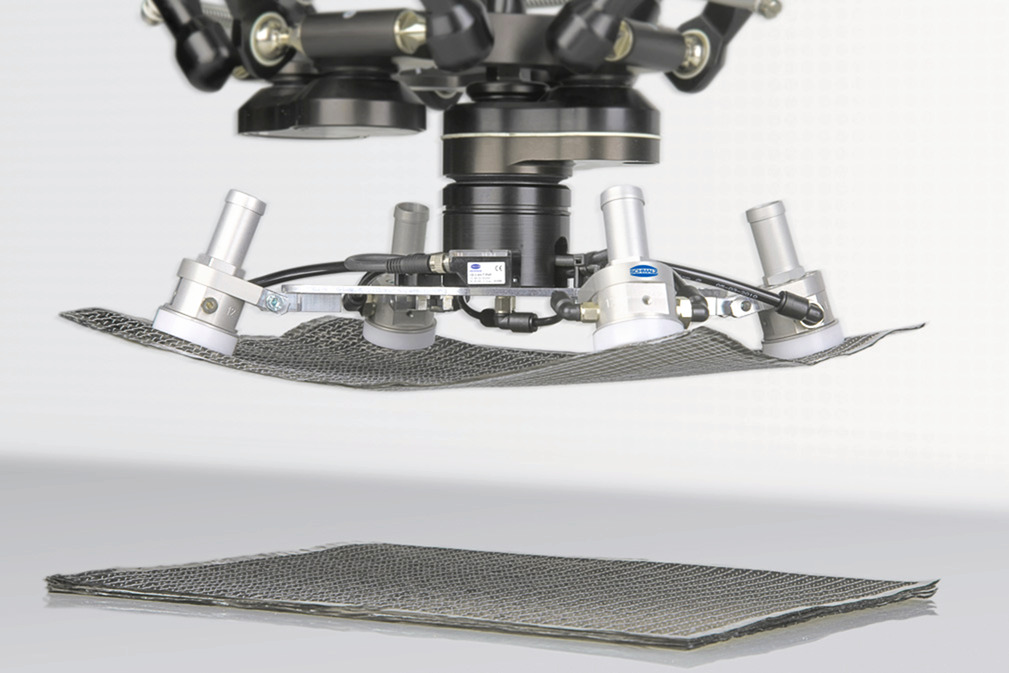

시트메탈 핸들링용 진공 패드

- 시트메탈 핸들링

- 표면이 오목한 작업물 핸들링

- 고도의 동적 공정에서 횡력을 최대 흡수

Vacuum Technology for Automation

The automotive industry is one of the most important commercial sectors, with a densely networked supplier industry. Generally, the industry is separated into vehicle manufacturers, component suppliers and line builders. Due to the ever growing number of different variants and increased manufacturing capacities , vehicle manufacturers are increasingly focused on global platform strategies. As part of these strategies, plant concepts and parts can be reused, which then increases the numbers of parts produced.

Strict emission regulations and dwindling resources also require the increasing electrification of vehicles. In addition, production methods are changing: production lines are becoming more flexible and cars are becoming lighter, e.g. through hot forming.

Vacuum Lifters and Crane Systems

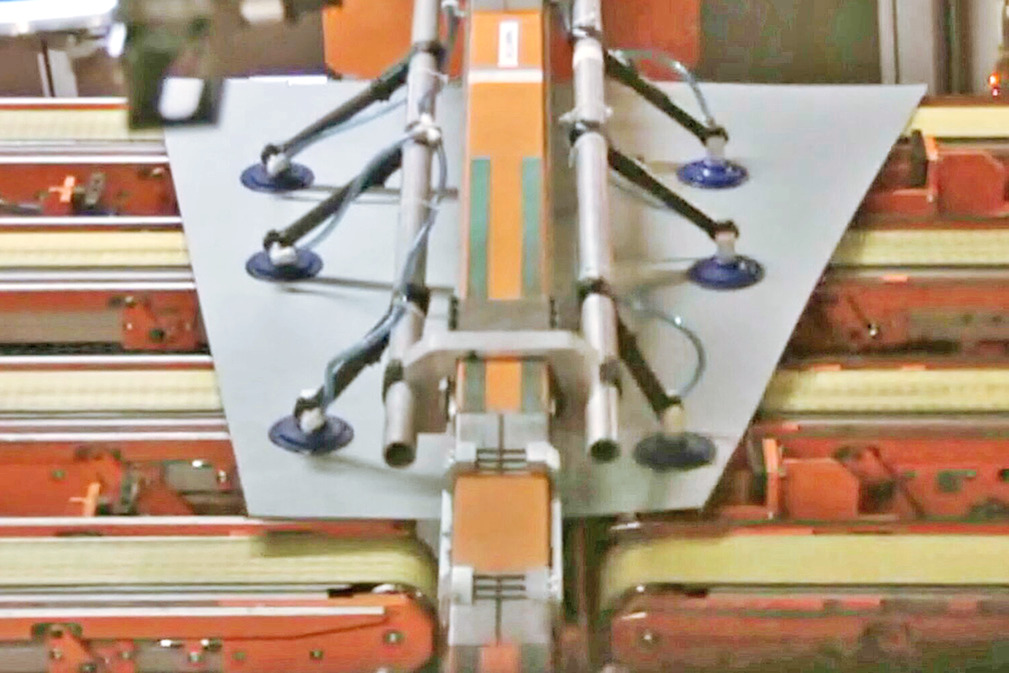

Various manual processes in the automotive Industry are involved in manufacturing workflows: For example, components such as roofs are unloaded from presses and loaded to the carriers; in in-house logistics, small load carriers such as boxes or crates are moved, and components such as windows, batteries or brake disks are supplied to the line. The high cycle rate and the weight or shape of the workpieces involved in these tasks can strain the health of employees.

Manually controlled vacuum lifters relieve operators of the weight of workpieces, allowing them to work ergonomically and without physical strain. The simple operation of vacuum lifters allows coils, metal sheets, boxes and crates to be quickly gripped and moved. Depending on the type, the vacuum lifters allow the workpieces to be swiveled horizontally by 90° or rotated 180°.

Highly Dynamic and Transparent Processes

Resistant to Dirt and Oil

Good Adaptation to Complex Workpiece Shapes

Temperature Resistance During Hot Forming

Safety and transparent processes

High Energy Efficiency During Vacuum Generation and Handling, for example in joining processes or during emergency stops

Reliable and Transparent processes

High Ozone Resistance in all Materials Used

Vacuum Powered for Flexible and Cost Efficient Operation

Handling and Installing Front, Side and Rear Windows

Handling and Placing Automotive Batteries

Automated logistics processes with Cobots

Logistics and intralogistics in the automotive plant

Safe handling of heavy components

Manual handling in the press store and paint store

Manuelle Manual handling in assembly

사용자 친화적이고 유익하며 실용적인 다양한 산업 분야의 제품 적용 사례를 발견하십시오.

적합한 동영상을 찾지 못하셨나요? 그렇다면 미디어 센터를 살펴보세요.