Area Gripping Systems FXCB

- Area gripper with integrated vacuum generator

- Suitable for operation with collaborative robots

- Sealing element: Sealing foam or suction cups

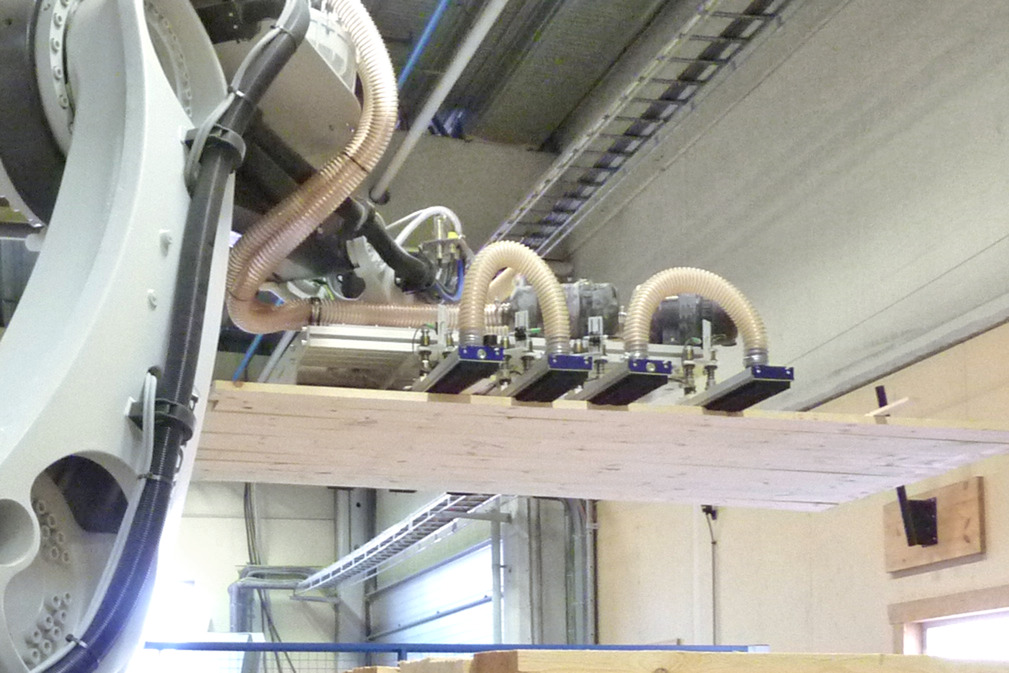

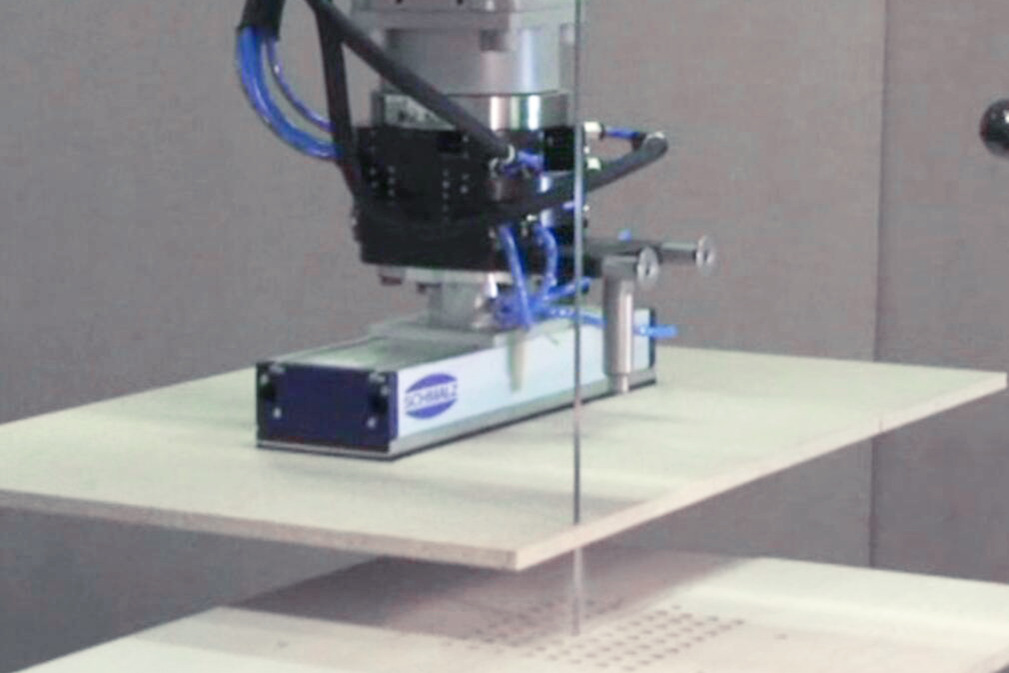

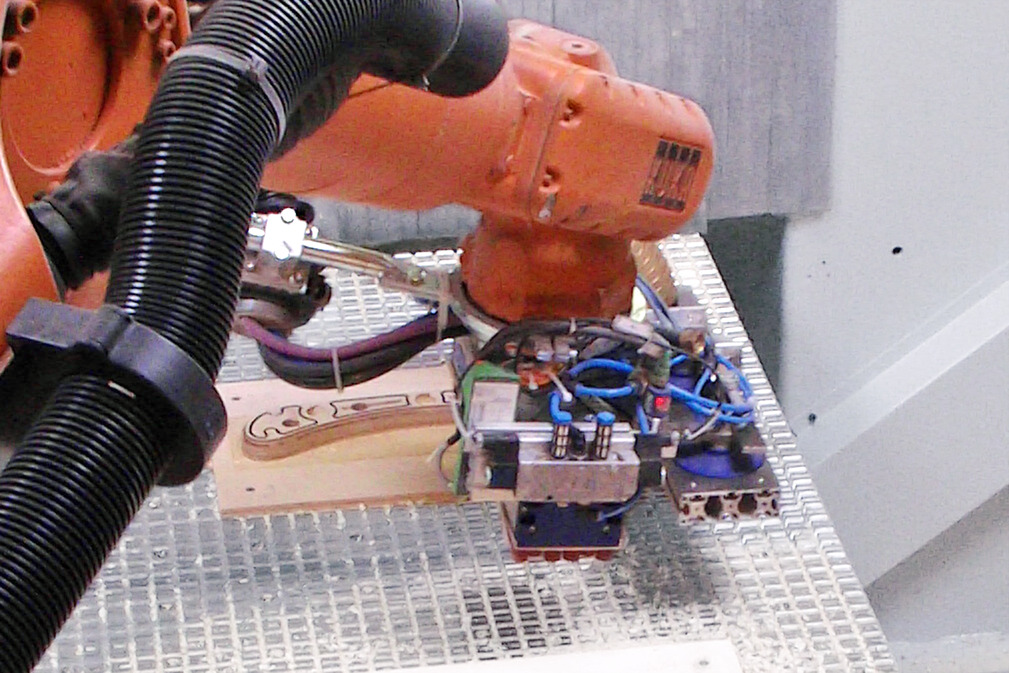

In the process of manufacturing doors, the workpieces are loaded into a CNC machining center. The doors have different dimensions and can include gaps, such as spaces for windows. The vacuum area gripping system FXC securely grips the various workpieces with ease.

The gripper system can handle different workpieces without requiring changes to the gripper. Even doors with a frame width of only 80 mm are no problem for the gripper system. The foam grid serves as the sealing element between the gripper and the workpiece. This sealing foam compensates for gaps in the workpiece which could cause leaks. The integrated valves open and close individual vacuum points according to how the gripper is covered.

The integrated vacuum generation creates a strong holding force with low energy consumption. The large-area gripping system with integrated vacuum generation reduces energy requirements by up to 50% compared to other conventional gripper systems on the market.

Discover application examples of the product in various industries - user-friendly, informative and practical.

No suitable videos found? Then take a look at our media center.