Press releases

In our press area you will find current information about our products and our company.

For further information, our press kits and interview requests, please contact our press team at any time(presse@schmalz.de).

1 - 12 from 152 results

The Managing Directors of the subsidiaries met for the 47th time this week at the traditional Schmalz World Management Meeting (WMM) in Glatten. There, they sounded the attack: in 2026, the globally active family company wants to continue to grow. One country received a special motivational injection for this.

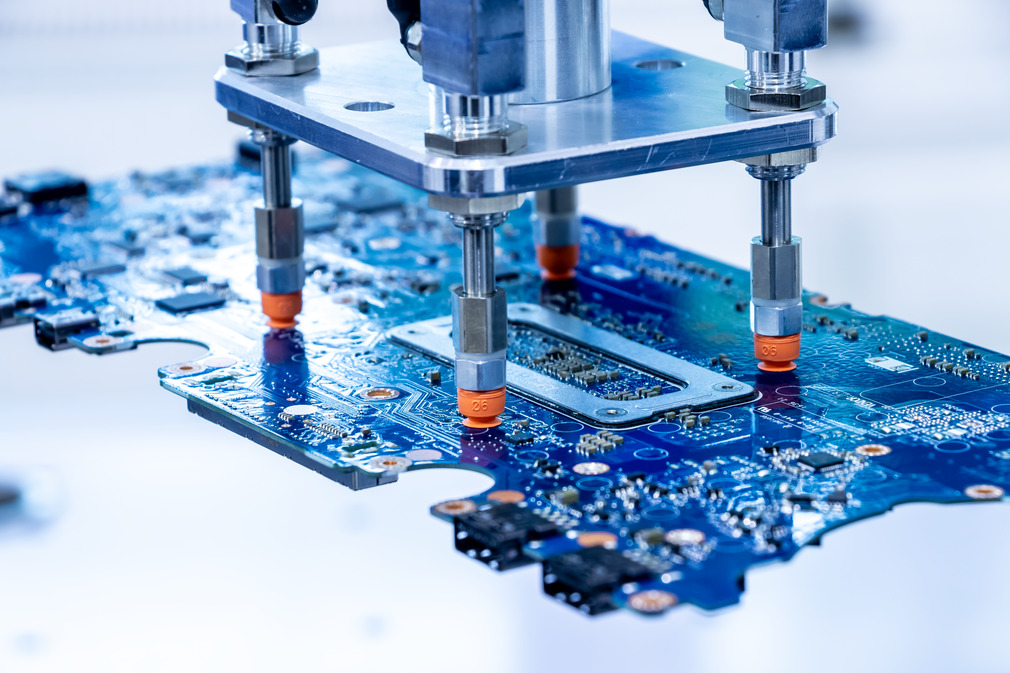

Electronics production: ESD-safe and leaving few marks

Perfect handling of sensitive electronics - with the new suction cup material HT1-ESD from Schmalz. The material releases several critical problems in electronics production at the same time: it leaves hardly any marks on components, reliably protects against electrostatic discharge (ESD) and withstands temperatures up to 170 degrees Celsius.

IO-Link Wireless – Schmalz relies on integrated technology without additional components

Wireless communication, limitless possibilities: With IO-Link Wireless, Schmalz is making the factory of tomorrow a reality today. Michael Pojtinger, Head of Business Development Process, Vacuum Automation, explains in an interview why the technology is a game changer for productivity and flexibility.

Handling efficiently, working ergonomically

Anyone who manually loads or unloads dozens of containers every day knows the problem: heavy cardboard boxes, uncomfortable positions, exhausted employees. The portable conveyor systems Destuff-it™ and Restuff-it™ provide a remedy and pay for themselves faster than expected. With them, Schmalz offers a solution that achieves three goals at the same time: higher productivity, better working conditions and measurable cost benefits.

Schmalz Energy Storage receives award at the Baden-Württemberg Environmental Technology Prize

The Glatten-based company has been awarded the Baden-Württemberg Environmental Technology Prize in the "Energy Efficiency" category for its highly efficient and scalable redox flow stack. With this solution, Schmalz is bringing the most powerful stack in Europe onto the market.

Even more flexible: Schmalz expands the range of applications of the VCBL-GL vacuum block

Vacuum specialist Schmalz has further developed the VCBL-GL vacuum block. The new generation impresses with a modular design, an extensive spare parts catalog and a wider range of applications - for more flexibility and lower costs over the entire life cycle.

Less engineering effort, more efficiency

Digital Engineering Service from Schmalz – Engineering process simply automated: The web-based Digital Engineering Service from Schmalz designs tailored gripping solutions for any number of different sheet metal parts digitally and automatically. This allows users to save up to 80 percent of engineering time and achieve their goals effortlessly.

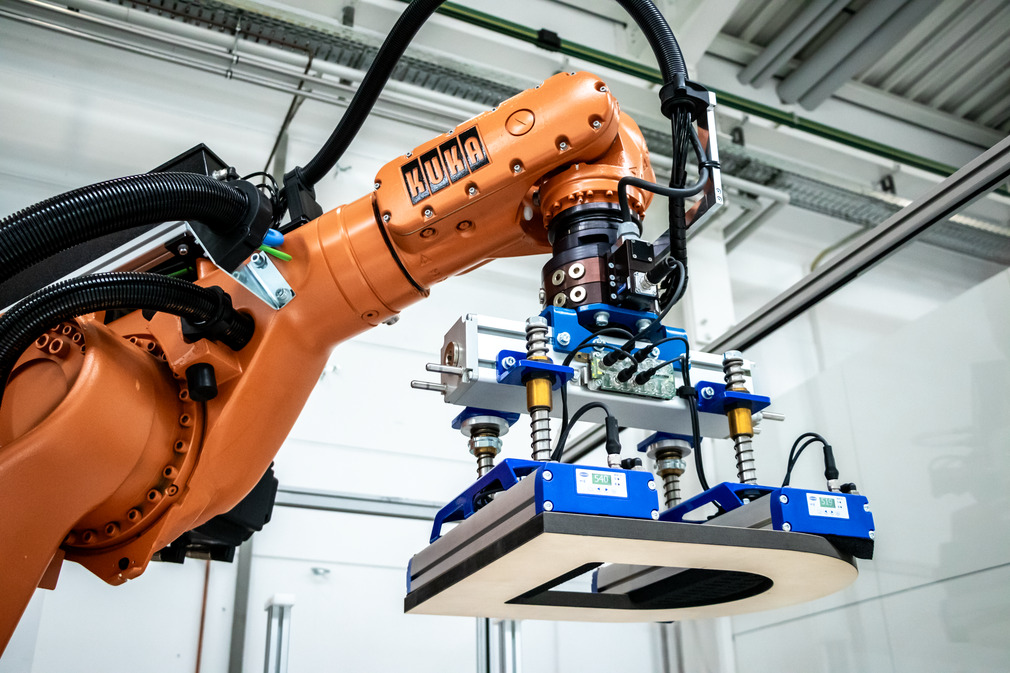

EOAT is the key to flexible automation

Dr. Maik Fiedler is a member of the company management and head of the Vacuum Automation business unit at Schmalz. In this interview, he explains the strategic importance of End of Arm Tooling (EOAT) for automation and describes how Schmalz designs the connection between robot and workpiece.

Area grippers: pack flexibly, save efficiently

Grip whatever comes your way: Different materials, changing workpieces and increasing cost pressure require systems that can adapt flexibly. With the vacuum area gripping systems FA-X / FA-M, Schmalz is launching two solutions that move parts of all kinds safely and save energy at the same time.

Schmalz wins swiss DINNO Award 2025 for innovative Solution Kit ivOS Sheet Metal

The subsidiary abroad Schmalz Switzerland was presented with the coveted swiss DINNO Award at the opening ceremony of SINDEX 2025, the leading Swiss trade show for industrial automation in Bern. The innovation prize recognizes the Solution Kit ivOS Sheet Metal, which sets new standards in automated sheet metal processing.

Half-time for "ReduCO2": Using digital tools to achieve cost-efficient climate protection

Regional research project shows initial results on the way to economically sustainable energy systems.

Powerful performance: leeches as a model for vacuum technology

Improving efficiency is a central research topic - for example in vacuum technology. Schmalz continuously optimizes its systems and looks beyond the horizon when developing them. A current project is focusing on the suction organs of leeches.