- 새로운

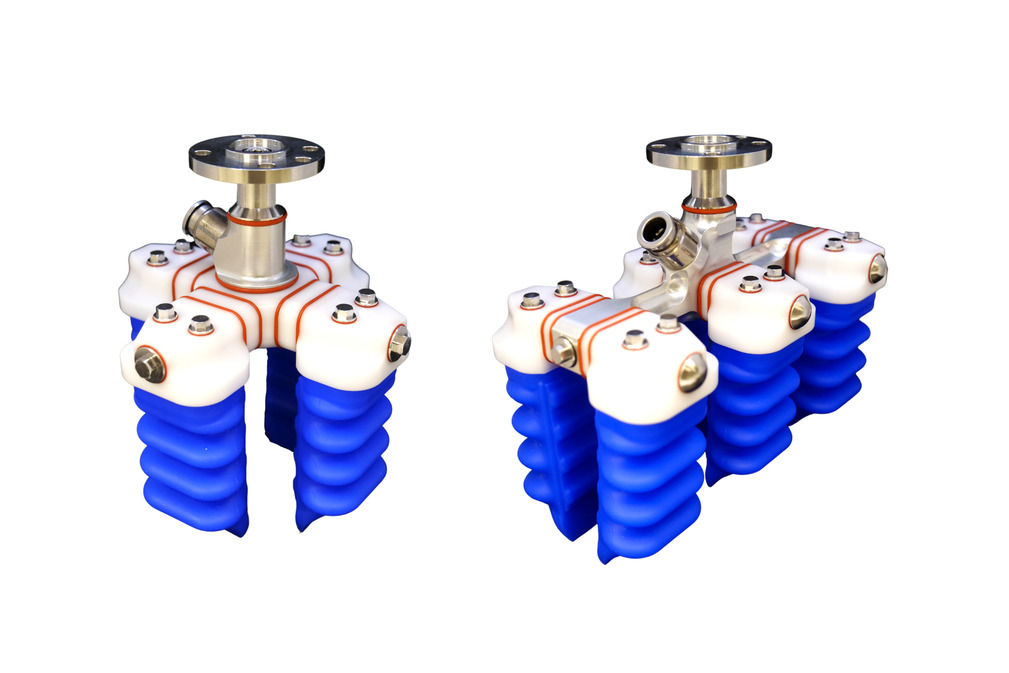

핑거 그리퍼 mGrip

- 최대 10kg의 적재 용량

- 최대 300mm의 작업물 폭

- 분당 최대 120픽의 그립 속도

- FDA 준수 재질(POM, 실리콘, 스테인리스 스틸)로 제작된 그리퍼, 보호 등급 IP69K

Vacuum technology has become an integral part of today's food industry. Vacuum is not only important for the hermetic packaging of food products, but also plays a crucial role during earlier stages such as sorting products on conveyor belts, transferring them, or placing them into packaging.

Vacuum technology for automation

To gently handle a wide variety of food products such as muffins, waffles, cookies, chocolates, or even eggs, suction cups must be able to flexibly adapt to the surface characteristics of each item. This prevents leakage and ensures safe and fast product transfer.

In the food industry, the highest demands are placed on the suction cup materials to prevent contamination of food products. Schmalz vacuum suction cups for the food industry are manufactured from FDA-compliant materials and comply with EC Regulation No. 1935/2004.

Vacuum lifters and crane systems

Ergonomic vacuum lifters optimize the material flow at every stage of the food industry process, whether it's during the picking of packaged raw materials, the processing and production of the final product, or packaging and shipping.

Thanks to FDA-approved materials and GMP-compliant design (Good Manufacturing Practice), our vacuum lifters are also suitable for use in demanding wet and hygienic areas and meet the strict requirements of the food industry.

새로운

mGripedia: 식품 자동화를 위한 중앙 애플리케이션 플랫폼

애플리케이션 플랫폼 mGripedia에서핑거 그리퍼 mGrip의 다양한 활용 가능성을 확인해 보세요. 수많은 실제 사례를 통해 핑거 그리퍼 mGrip이 다양한 제품을 얼마나 유연하고 위생적이며 안정적으로 핸들링하는지 직접 경험해 보십시오.

기대하세요:

No food contamination

The materials used must be FDA-compliant and comply with EC Regulation No. 1935/2004. Schmalz suction cups made of the materials SI, SI-HD and SI-MD are suitable for food handling.

Metal-detectable suction cups

Suction cups made of the metal-detectable silicone SI-MD are particularly suitable for direct contact with food. The material SI-MD contains a small amount of metal oxide, which is recognized by commercially available metal detectors. If the suction cup enters the tray, it is quickly detected. This helps prevent contamination of food

Adaptation to surface texture

Food of the same type, such as chocolate pralines with or without topping or decorations, often differ in shape and surface texture. The suction cup used must be flexible enough to adapt to these variations in order to avoid leakage and securely grip the food.

Sucking in components of dry food

When handling dry food, individual crumbs are repeatedly sucked into the gripper. To prevent contamination of the gripper as well as other food items, the crumbs must be properly removed. We also offer a solution for this.

Cleaning the gripper

To prevent contamination of the food, regular cleaning of the suction grippers is recommended. Harmless cleaning agents should be used for this purpose.

Inbound goods: Unloading, sorting, storage

Handling in hygienic areas

Handling in explosion-proof areas

Outbound goods: Packaging and shipping

브로셔: 식품 핸들링의 위생 및 안전

두 개의 브로셔를 통해 공정의 모든 단계에서 식품 제품을 안전하고 인체공학적 핸들링할 수 있는 검증된 솔루션을 소개합니다. 수동 리프팅이든 자동 그리핑이든 진공 기술은 위생이 중요한 공정을 서포트하고 재질과 공정에 대한 최고 기준을 충족합니다.

지금 브로셔를 다운로드하여 자세히 알아보세요.