- NIEUW

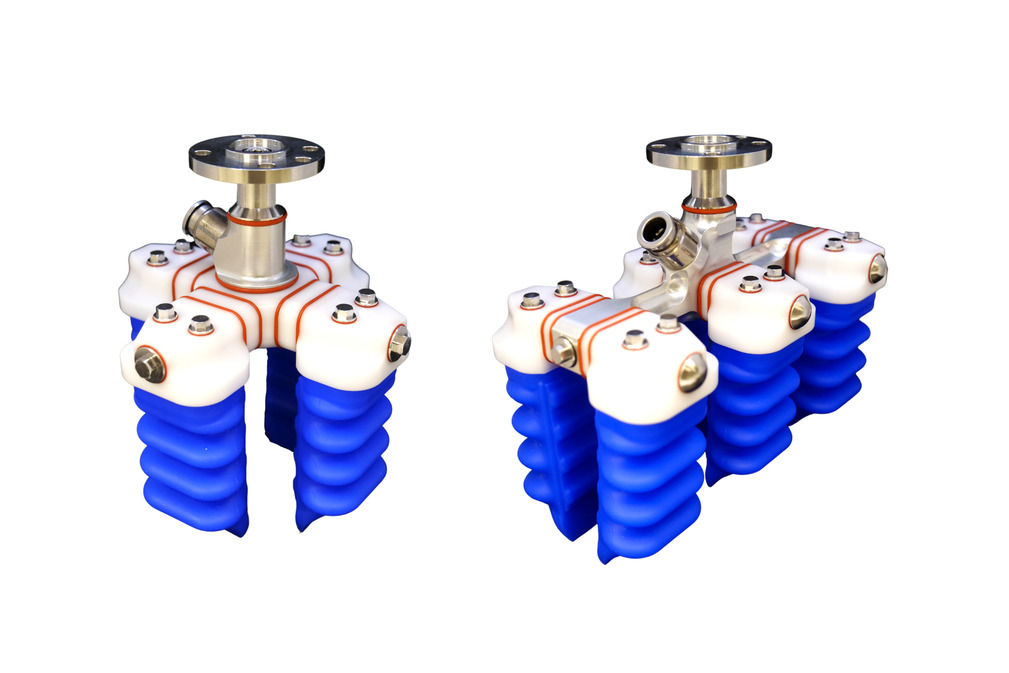

Vingergrijpers mGrip

- Laadvermogen tot 10 kg

- Werkstukbreedte tot 300 mm

- Grijpsnelheid tot 120 picks per minuut

- Grijper gemaakt van FDA-conform materiaal (POM, siliconen, roestvast staal), beschermingsklasse IP69K

Vacuum technology has become an integral part of today's food industry. Vacuum is not only important for the hermetic packaging of food products, but also plays a crucial role during earlier stages such as sorting products on conveyor belts, transferring them, or placing them into packaging.

Vacuum technology for automation

To gently handle a wide variety of food products such as muffins, waffles, cookies, chocolates, or even eggs, suction cups must be able to flexibly adapt to the surface characteristics of each item. This prevents leakage and ensures safe and fast product transfer.

In the food industry, the highest demands are placed on the suction cup materials to prevent contamination of food products. Schmalz vacuum suction cups for the food industry are manufactured from FDA-compliant materials and comply with EC Regulation No. 1935/2004.

Vacuum lifters and crane systems

Ergonomic vacuum lifters optimize the material flow at every stage of the food industry process, whether it's during the picking of packaged raw materials, the processing and production of the final product, or packaging and shipping.

Thanks to FDA-approved materials and GMP-compliant design (Good Manufacturing Practice), our vacuum lifters are also suitable for use in demanding wet and hygienic areas and meet the strict requirements of the food industry.

Nieuw

mGripedia: Het centrale applicatieplatform voor voedselautomatisering

Ontdek de veelzijdige applicatiemogelijkheden van de vingergrijper mGrip op ons applicatieplatform mGripedia. Ontdek zelf aan de hand van talrijke praktijkvoorbeelden en ervaar hoe flexibel, hygiënisch en betrouwbaar de vingergrijper een grote verscheidenheid aan producten handling - misschien zelfs het uwe!

Kijk uit naar:

No food contamination

The materials used must be FDA-compliant and comply with EC Regulation No. 1935/2004. Schmalz suction cups made of the materials SI, SI-HD and SI-MD are suitable for food handling.

Metal-detectable suction cups

Suction cups made of the metal-detectable silicone SI-MD are particularly suitable for direct contact with food. The material SI-MD contains a small amount of metal oxide, which is recognized by commercially available metal detectors. If the suction cup enters the tray, it is quickly detected. This helps prevent contamination of food

Adaptation to surface texture

Food of the same type, such as chocolate pralines with or without topping or decorations, often differ in shape and surface texture. The suction cup used must be flexible enough to adapt to these variations in order to avoid leakage and securely grip the food.

Sucking in components of dry food

When handling dry food, individual crumbs are repeatedly sucked into the gripper. To prevent contamination of the gripper as well as other food items, the crumbs must be properly removed. We also offer a solution for this.

Cleaning the gripper

To prevent contamination of the food, regular cleaning of the suction grippers is recommended. Harmless cleaning agents should be used for this purpose.

Inbound goods: Unloading, sorting, storage

Handling in hygienic areas

Handling in explosion-proof areas

Outbound goods: Packaging and shipping

Brochures: Hygiëne en veiligheid in de handling van levensmiddelen

Twee brochures shwocase bewezen oplossingen voor veilige en ergonomische handling-oplossingen voor levensmiddelen in elke fase van het proces. Of het nu gaat om handmatig tillen of automatisch grijpen, vacuümtechniek ondersteunt hygiënekritische processen en voldoet aan de hoogste normen voor materiaal en processen.

Download nu brochures voor meer informatie.

Vacuümtechniek voor automatisering Vacuümheffers en grijpersystemen