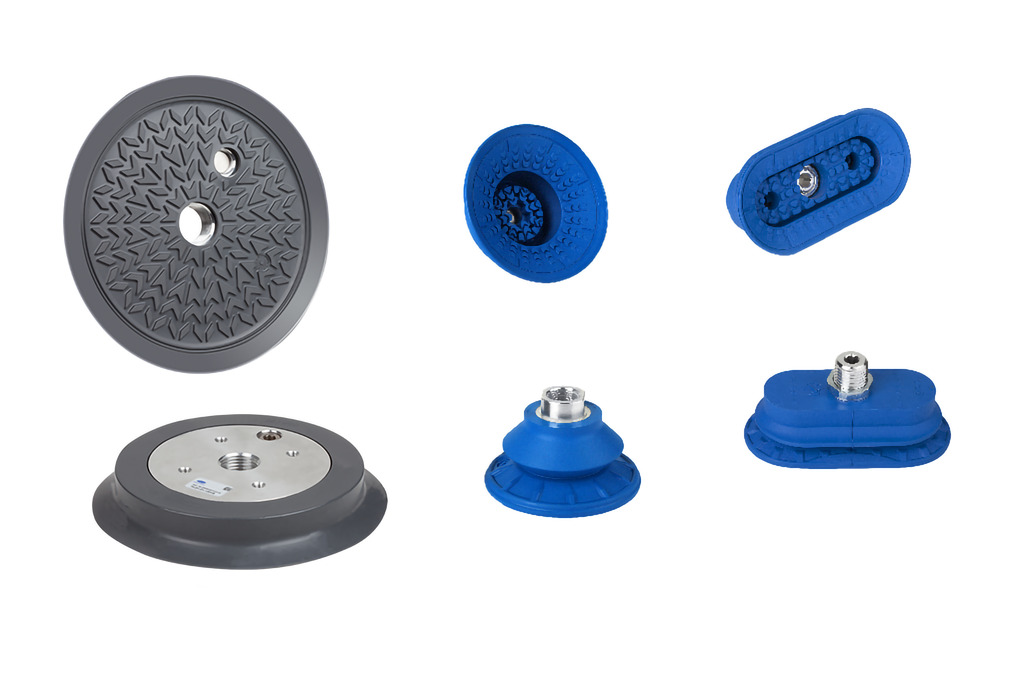

유리 핸들링용 진공 컵

- 평평한 유리 부품 핸들링용

- 강한 고정력과 횡력

- 자국을 거의 남기지 않는 부품

Vacuum Technology for Automation

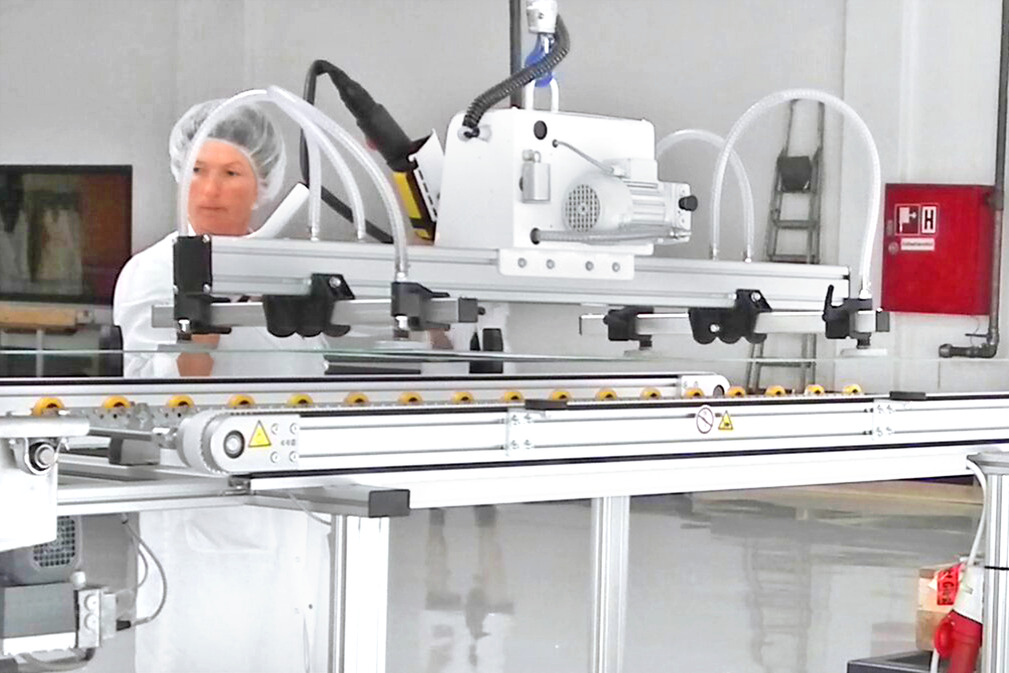

Glass is a universal material whose physical and chemical properties allow it to be used in a wide variety of different applications. Not only the amount of glass used in architecture and the automotive sector is increasing the fastest, but also the use of glass in displays is also very much on the rise.

Glass workpieces are very sensitive. In most cases, only vacuum technology can handle glass without damage and leaving few marks. Schmalz offers the right solution for the requirements of the individual production processes. We focus on the segments float glass, building glass, automotive glass, solar glass, display glass and container glass.

Vacuum Clamping Technology

Schmalz clamping solutions ensure flexible and efficient production processes in glass processing. Vacuum blocks with special friction pads are wear resistant and guarantee precise results, even in challenging operating conditions. High lateral force absorption and low height tolerances ensure optimal quality while grinding glass edges. Minimum set-up times enable the output of the lines to be increased.

Vacuum Lifters and Crane Systems

Fragile windows and glass sheets require an especially gentle handling process. Vacuum handling allows a single person to easily move even heavy glass components without the risk of breakage.

새로운

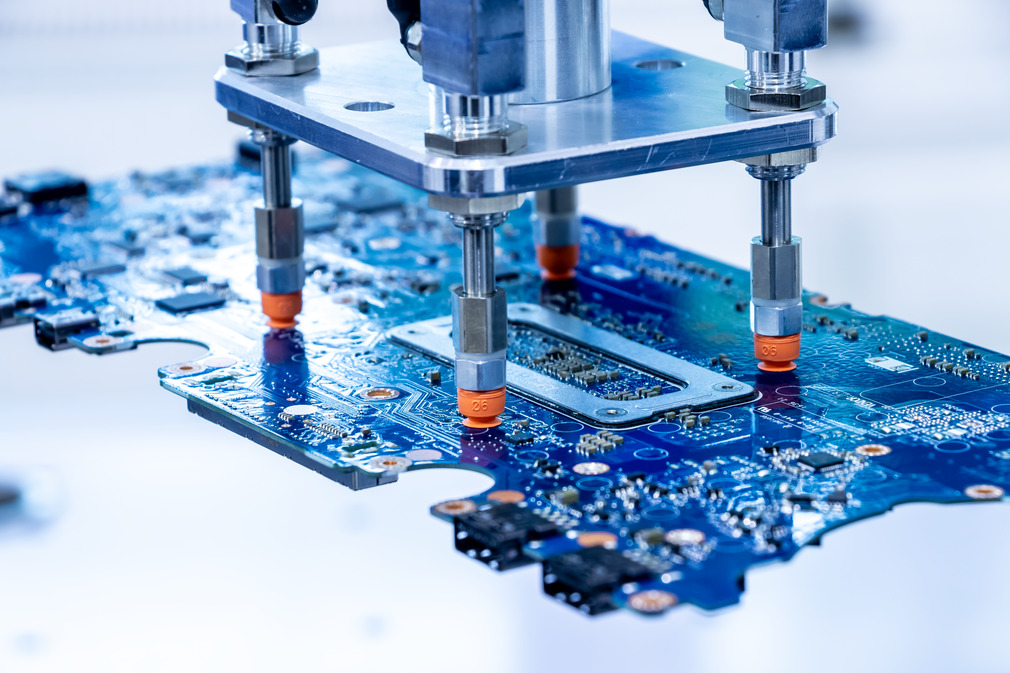

민감한 전자 제품의 완벽한 핸들링 - 자국 최소화, ESD 보호 극대화

전자 제품 제조에는 두 번째 기회가 없습니다. 작은 자국 하나, 정전기 방전 한 번이면 전체 배치가 망가집니다. 저희는 그렇지 않습니다!

혁신적인 진공패드 재질로 만들어진 HT1-ESD는 이러한 문제를 비롯한 여러 가지 문제를 해결합니다: 원치 않는 자국과 ESD 손상으로부터 작업물을 보호합니다. 진공패드를 사용하면 다음과 같은 이점이 있습니다:

재료 개발에 대한 광범위한 전문성을 바탕으로 한 진공패드 재질 HT1-ESD는 최첨단 기술을 상징하며 전자 제품 제조의 새로운 표준을 제시합니다.

High shear forces even on separation powder

To avoid the adhesion force between stacked glass sheets, the sheets are coated with separation powder. The special suction cups SGF and SAB generate high shear forces even when separation powder is used. The specially developed profile of the suction cups ensures high friction for a secure handling.

Mark-free handling

Marks on the surfaces of the glass sheets should be avoided throughout the entire production process. Suction cups made of the markless material HT1,can also be used at temperatures of up to 170°C. In combination with a low surface pressure, the suction cups SGF and SAB are ideal for meeting these requirements. With the suction cup covers SU, any contact between the suction cup and the glass can be prevented. We developed a special foam layer with a protective coating so that the vacuum area gripping system can be used for handling soft coatings, such as those used for low emissivity windows, because of its large contact surface and minimal surface pressure.

Short cycle times and high precision

These handling processes require short cycle times. The compact ejector SXMPi offers an integrated suction and blow-off function. This minimizes suction and release times, as well as energy consumption, since the integrated automatic air-saving function means that the ejector is only activated when vacuum is needed. The intelligent compact ejector also features numerous functions for energy and process control.

Plant availability and low energy costs

Not only to avoid capping, but also to detect possible contamination and capping is of central importance for plant availability. The detection allows an early and targeted avoidance of an unplanned plant shutdown. The vacuum generator SCTSi, a terminal with up to 16 individual vacuum circuits, enables direct integration into the control system via IO-Link or Ethernet. Thus, the internally processed and pre-interpreted data can be transferred directly to the control system and, for example, a leakage in a suction circuit can be detected early on. We also speak here of EPC - Energy and Process Control. In addition, the pneumatic vacuum generators have an integrated air-saving control, thus minimising energy consumption.

In addition to powerful holding forces, the height tolerance also plays an important role in the grinding process of glass, because even minimal height differences can cause significant fluctuations in quality. With the vacuum blocks VCBL-G, the workpieces are clamped safely and precisely. In addition to the high shear force, the vacuum blocks ensure minimal height tolerances for a high quality of theglass edges.

Vacuum Block VCBL-GL

A variety of manual handling steps are involved in the manufacturing process and final installation of building glass. Fast, ergonomic handling plays a key role in these processes. Schmalz’ manual lifting device VacuMaster Window offers the optimum solution for every process, from the loading of cutting tables to the installation of windows – quickly, ergonomically and safely.

VacuMaster Window 200/300

VacuMaster Window Comfort 500

Outdoor handling: VacuMaster Glass

High shear forces on separation powder

To avoid the adhesion force between stacked glass sheets, the sheets are coated with separation powder. The special suction cups SGF and SAB generate high shear forces even when separation powder is used. The specially developed profile of the suction cups ensures high friction for secure handling. The low stroke of the suction cups SGF enables maximum precision while the flexible bellows of the SAB also adapt to shaped glass, e.g. side lites.

Mark-free handling

Marks on the surfaces of the glass sheets should be avoided throughout the entire production process chain. Suction cups made of the markless material HT1can also be used at temperatures of up to 170°C (e.g. unloading the bending furnace). In combination with a low surface pressure, the suction cups SGF and SAB are ideal for meeting these requirements. With the suction cup covers SU, any contact between the suction cup and the glass can be prevented. We developed a special foam layer with a protective coating so that the vacuum area gripping system can be used for handling soft coatings, such as those used for low emissivity windows, because of its large contact surface and minimal surface pressure.

Short cycle times and high system availability

These handling processes require short cycle times. The compact ejector SXMPi offers an integrated suction and blow-off function. This minimizes suction and release times, as well as energy consumption, since the integrated automatic air-saving function means that the ejector is only activated when vacuum is needed. The intelligent compact ejector also features numerous functions for energy and process control as well as predictive maintenance funtions to increase system availability.

Energy-saving and quiet

In the assembly processes for automotive glass, manual and automated processes are often closely connected. The glass has to be fixed in place for a long period. The compact ejectors SEAC-RP offer suction and blow-off functions in minimal installation space, enabling them to be used right on the suction cup. The integrated pneumatic air-saving regulation reduces the compressed air consumption to a minimum, while ensuring that the system produces very little noise.

Gentle area gripping

The area gripping systems FXP/FMP grip large areas of the glass so that only low local surface pressure is generated. This allows even sensitive coatings or imprints to be handled without damage. Thanks to the integrated valve technology, the grippers can also handle workpieces that are smaller than the actual gripping surface. The universal gripper FXP also offers an integrated vacuum generator.

In addition to powerful holding forces, the height tolerance also plays an important role in the grinding process of glass, because even minimal height differences can cause significant fluctuations in quality. With the Quick-Change System SQC and the vacuum blocks VCBL-GL, the workpieces are clamped safely and precisely. In addition to the high shear force absorption, the vacuum blocks ensure minimum height tolerances for a high quality of the glass edges.

Vacuum Block VCBL-GL

Quick-Change System SQC

In the production of automotive glass, there are a large number of manual handling steps in addition to the automated application. Especially in the area of assembly processes, such as overmoulding seals or attaching holders. Of course, manual handling also plays a central role in the logistics and packaging of the glass.

Vacuum Tube Lifter JumboFlex

Vacuum Tube Lifter JumboErgo

Highforces and maximum acceleration rates

These handling processes require minimal cycle times. The glass also has to be gripped quickly and then handled safely and precisely with high acceleration rates. Schmalz’ specially designed thin glass gripper STGG has a large suction area to absorb high shear forces for fast, highly precise handling of glass.

Gentle, contamination-free handling

Any contamination of the glass – before or after the coating – significantly affects the functionality of the displays. For this reason, the grippers STGG are equipped with a contact surface made of contamination-free PEEK. The large suction area of the grippers enables a high suction force to be generated with low vacuum levels. This allows handling with low surface pressure. In addition, Schmalz offers a broad range of suction cups made oft he markless material HT1, that leaves no visiblemarks. The inner support structure oft he suction area of the suction cups SGPN makes it ideal for thin glass.

System availability and low energy costs

These handling processes require short cycle times. The compact ejectors SCPSi and SCPM offer an integrated suction and blow-off function. This minimizes suction and release times, as well as energy consumption. The integrated automatic air-saving function means that the ejector is only activated when vacuum is needed. In addition, the intelligent compact ejector features an IO-Link interface for reading out process data and configuring the ejector. The small size of the ejector allows it to be positioned close to the suction cup for minimal evacuation times.

Flexible handling in assembly processes

The large-area gripping systems FXP/FMP grip a large area of the glass. This generates only a low local surface pressure so that even sensitive coatings or imprints can be handled without damage. An optionally available protective coating minimizes contamination. The integrated valve technology means that the grippers can handle even workpieces that are smaller than they are, allowing different glass workpieces to be gripped flexibly. The gripper FXP also offers an integrated vacuum generator based on the Venturi priciple.

Low-contact handling

By taking advantage of the Bernoulli principle, SBS floating suction cups allow you to handle workpieces with very little contact. The suction cup floats on an air cushion, and horizontal forces can be transmitted by means of an elastomer buffer made of HT1. High flow rates combined with low vacuum permit gentle handling and long-range effectiveness for safe separation of glass sheets.

ESD compliant handling

Suction pads made of the ESD-compliant material NBR-ESD have a resistance range of 106 to 109 Ω and are also free of conductive soot. This means that the suction pads made of the yellow material NBR-ESD not only provide a defined leakage resistance, but also prevent damage to components due to soot. In combination with the spring plungers FSTIm and FSTImc, the suction pads offer reliable point-to-point and point-to-ground resistance in the ESD range.

Flexible and adaptable

Different shapes of glass and layer structures are no problem for the large-area grippers with patented combi foam. The large-area gripping systems FXP/FMP can be used to grip an enormous range of different glass workpieces without complex gripper changes or modification processes during production. The adaptable foam levels out the height differences within a layer. The integrated valve technology allows reliable handling even with low coverage oft he suction area, for example handling just one glass out of an entire layer.

Gentle handling

Even the thinnest glass, such as drinking glasses, must be transported without damage or tension. The large-area gripping systems FXP/FMP with soft foam contact surfaces are the optimal solution to this application problem. The necessary vacuum value is adjusted to the application to avoid high forces and tensions in the glass.

Short cycle times

The glass workpieces must be gripped, transported and released again with short cycle times. The integrated valve technology allows the layer grippers SPZ and the large-area grippers FXP/FMP to quickly generate the vacuum and then quickly and precisely reduce it using the integrated blow-off function.

Handling intermediate layers

In most applications, not only the workpieces themselves, but also intermediate layers such as cardboard or plastic must be handled with the same gripper system. The integrated valve technology of the grippers allows different intermediate layers to be gripped directly. In addition, suction cups can be added to the gripping system to hande intermediate layers.

사용자 친화적이고 유익하며 실용적인 다양한 산업 분야의 제품 적용 사례를 발견하십시오.

적합한 동영상을 찾지 못하셨나요? 그렇다면 미디어 센터를 살펴보세요.